FUVALVE offers series of valve for abrasive,high-wear and erosion applications.The main product range of abrasion-resistant valves that Fuvalve offers are ceramic lined valve series and pinch valve series.

1.Fuvalve ceramic lined valve for abrasive applications,the material of valve body can be WCB,SS304,SS316,SS316L or other alloy steel fully lined advance ceramic,and the sealing face of valve ball,butterfly disc or gate disc lined ceramic.

FUVALVE Structural Ceramic lined Valves(materials Al2O3 or ZrO2 Ceramic)

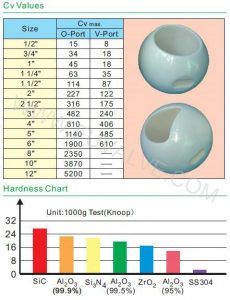

Advantages of structural ceramic valves include hi-economy, long life (2~4 times of Titanium Valves), increase resistance to corrosion, high temperature, wear and erosion etc.. They are commonly used in transportation systems of various acid, alkaline or saline gases, solutions, high working temperature steams and slurry, in the lines of oil industry, metallurgy, paper making, power station, refinery, etc. Structural ceramic ball valves are the ideal substitute for titanium and monel valves in corrosive environments. There are four types of driving performances, manual, pneumatic, pneumatic-spring return and electric. Various special valves can be designed on demand. Furthermore, various high wear-resistant, corrosion-resistant and high temperature-resistant ceramic components, hydraulic pressure sealing components can be provided as well.

Wear and corrosion resistance

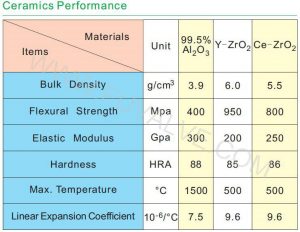

The valve sealing face and inner lining are all made of structural ceramics with hardness of HRA87 or above. So structural ceramic lined valves can withstand the impact of Hi-speed liquids and hard grains, displaying excellent performance on wear and corrosion resistance.

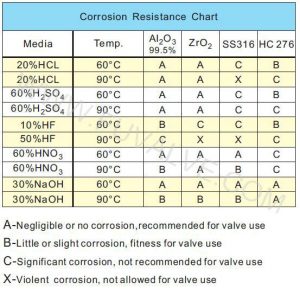

Corrosion resistance

The valve sealing face and the inner lining are all made of structural ceramics. The structural ceramics have excellent corrosion-resistance, except to glass-liquor and hydrofluoric acid.

Long working life

The static pressure test showed no leakage after long times opening-closing.

Wide-range of applications

The ceramic lined valves are applicable to various acid, alkaline or saline solutions, gaseous media, etc. Hard sealing ball valves can also be used in media with particles and fibers.

Main Industries served:

-Silicon powder

-Alumina powder

-Dry coal powder

-Limestone powder

-Cement

-Coalpowder injection

-Magnesium powder

-Quartz sand

-Metallurgical dust

-Petroleum solid catalyst

-Kaolin

2.Pinch valve.The core is the sleeve

Pinch Valves offer a cost-effective solution to flow control problems. The secret is in the rubber sleeve – the valve’s only wetted part. Actuation of the valve is accomplished by air or hydraulic pressure placed directly on the elastomer sleeve. The valve body acts as a built-in actuator, eliminating costly hydraulic, pneumatic, or electric operators. The sleeve’s rugged flexibility allows the valve to close drop tight around entrapped solids.

Especially in the area of the transport and regulation of abrasive solids, a particularly robust mixture of natural rubber in an abrasion-resistant valve is generally used. This mixture also guarantees a long service life even in case of problematic bulk materials. In addition to this very resistant rubber mixture, fabric elements that also increase the life time of the sleeve are worked in as well. In the process, the quality of the materials used for manufacturing determine the anti-abrasion behaviour of the sleeve and therefore its life time.

The service life of abrasion-resistant valves is determined by the respective transported materials and by the quality and/or anti-abrasion behaviour of the sleeves, which function inside the housings of the valves. The higher the quality and abrasion resistance of the sleeve, the shorter the downtimes and the lower the servicing costs for the valve since the maintenance and/or exchange intervals extend and the production downtimes therefore reduce.

The following industries rely on the reliable and economical functioning of abrasion-resistant valves:

- Mining industry for potash production

- Ceramic industry for the transport of sludge and solids

- Construction and cement industry for transporting cement, gravel, sand, concrete and bulk materials

- Food industry for the transporting of sugar and salt, for example

- And many more