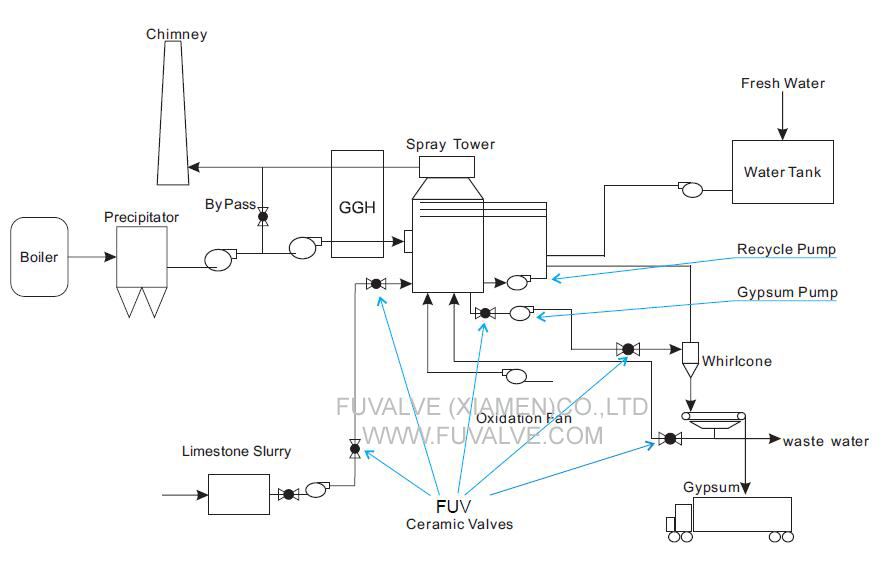

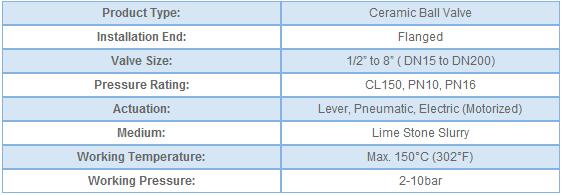

Ceramic ball valve for Flue Gas Desulfurization(FGD valve)

FGD is a process of treating flue gases with lime stone slurry to remove SOx, NOx and other pollutants and produce gypsum slurry as a by-product. One of the technological challenges in FGD system is the highly corrosion and abrasion of the slurry to the pipe lines and valves. Severe corrosion and abrasion can result in unacceptable high costs for replacement and maintenance. Therefore in many coal fired power plant by choosing the best corrosion-resistant and abrasion-resistant ceramic full lined ball valves and pipes will ensure the FGD system can be cost effective and stabilized.

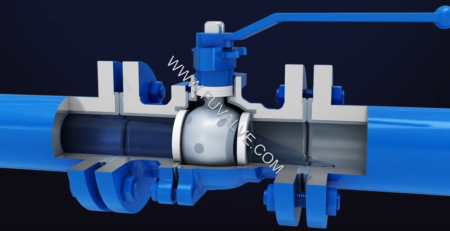

Body: ASTM A105

Ball: Zirconia (ZrO2) Ceramics

Seats and Lining: Alumina(99%Al2O3) Ceramics

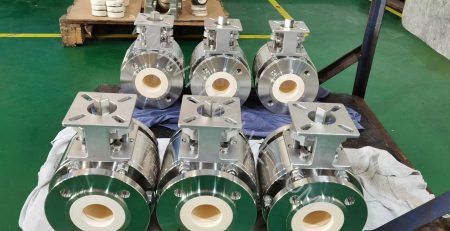

Our ceramic ball valve used for Flue Gas Desulfurization applicatinos:

Ceramic ball valve for Flue Gas Desulfurization(FGD valve)

This 3”-150LB ceramic full lined ball valve was returned to factory in May 2014 for a routine debugging and maintenance after three years installation in customer’s FGD system. The ceramic ball was still smooth and like mirror, there were no visible scratches and erosion. After re-debugging, this valve was sent back to customer for the 2nd service life period.

Typical Applications:

In many corrosive or/and abrasive applications, PTFE or PFA lined ball valves and metal seated ball valves are used, but limited to the material, these PTFE or PFA lined ball valves and metal seated valves cannot last for a long time due to severe abrasion and corrosion. Ceramic ball valve have excellent performance and much longer life time than soft seated and metal seated ball valves in most corrosive and abrasive applications. Some typical applications listed below (but not limited to these applications) where FUVALVE Ceramic ball valve have been widely used all over the world: Silicon Powder,Alumina Powder,Dry Coal Powder,Limestone Slurry,Gypsum Slurry,Plaster,Fly Ash,Mining Ore,Coal Powder Injection,Metallurgical dust,Thermal Power plant FGD,Petroleum Solid Catalyst,TiO2 suspension with sulfuric acid,Ammonia solution with powder,Hydrochloric Acid,Liquid Chlorine,Bulk Material.

-400x231.jpg)