C-type Ceramic lined half ball valve

- Description

- Inquiry

C-type Ceramic lined half ball valve

Product Profile

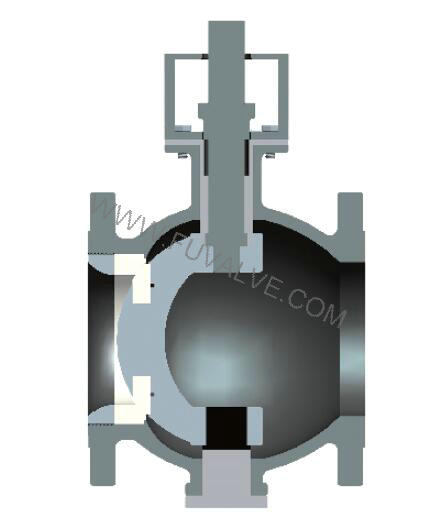

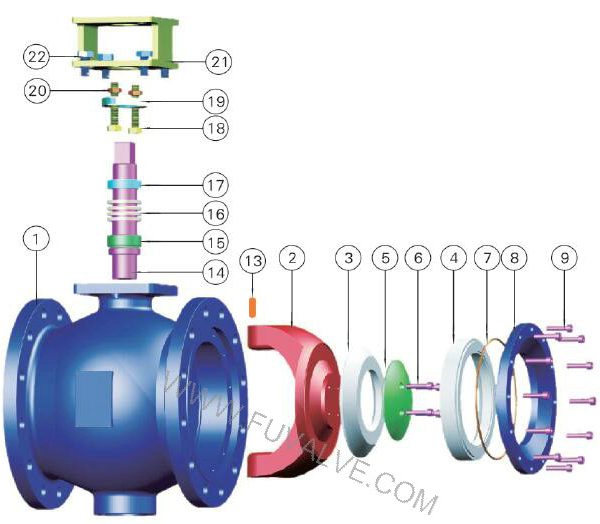

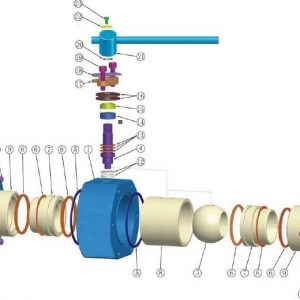

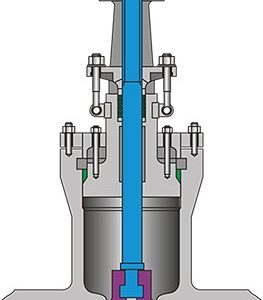

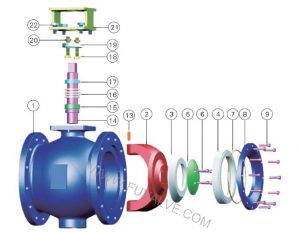

FUVALVE C-type Ceramic half Ball Valve Series with double eccentric design, torque sealing. Using double eccentric to produce cam wedge tightening effect to realize torque sealing. When closing, the C-type ball moves gradually relative to the seat, the tighter the clearance is, and the leakage grade of hard seal reaches VI. It is a typical spherical seal.

And, it has functions of cut-off and adjusting; It can regulate and control throtling in slurry medium with abrasive solid content, flbrous fluid, high viscosity and scale-prone slurry.

Product Characteristics

The C-type Ceramic Ball Valve with one or two-stage structure, single seat and no valve chamber. It has the properties of wear resistance, erosion resistance, high temperature resistance and crushing resistance.

Due to the straight-through design, when the valve is opened, there is no blocking element in valve chamber. And the surface of flow passage in C-ball has no rib, so there will be no sticking or blocking. When the valve closed, there is no material detention zone in valve chamber, which avoid material crystallization turning on unable to open.

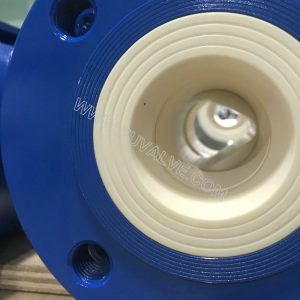

It has self- cleaning function. When the valve is opening, C-ball is tilted away from valve seat, and the fluid flushes sundries along the sealing surface totally. When the valve is closing, C-ball moves gradually relative to the valve seat, which can realize the shearing of the adhering sundries on the sealing pair to ensure the cleaning of the sealing pair, and the wear resistance of the solid C-type ceramic valve seat will not be damaged by intercepted objects.

Its actuator connection is through the bracket interface, which meets the IsO 5211 size standard, and can also be customized according to customers’ requirements.

C-type Ceramic lined half ball valve

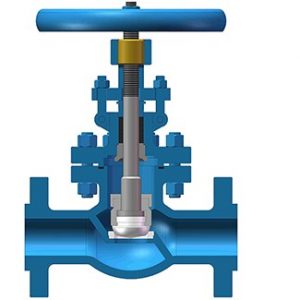

The Ceramic Control Partial Core Rotary Valve has the advantages of light switch, low friction, no contact between spherical surface and sealing seat when opening and closing, small torsion and flexible rotation.

When the sealing pair is opening and closing, there is shearing performance. Ceramics have self-cleaning and self-wetting properties which help to clean scales and adhesives on the sealing surface and maintain long-term tightness.

According to the wedge effect which created by eccentric core, the tighter the closure of C-ball and valve seat, the contact between seal pairs can be compensated by themselves.

Ceramic seal pairs adopt special processing technology with spherical seal to ensure VI closure level and better regulation performance.