Pressure Seal Bonnet Ceramic Globe Valves

- Description

- Inquiry

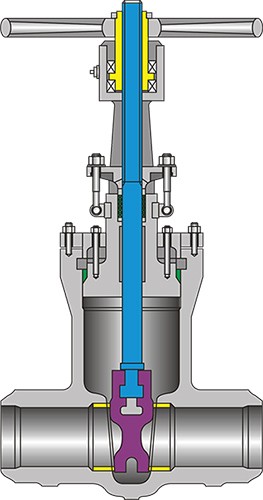

Pressure Seal Bonnet Ceramic Globe Valves

Specification:

Type | Bonnet Ceramic Globe Valves |

Size | DN50-DN300(1”-12”) |

Pressure Rating | PN10,PN16,PN25,PN40, PN63, PN100, PN160, CL150, CL300, CL600, CL900 |

Body Material | WCB, CF8, CF8M, CF3M, Hastelloy, Monel, Alloy 20, Titanium |

Trim Material | ZrO2 Ceramics, Al2O3 Ceramics, Tungsten Carbide, Si3N4 |

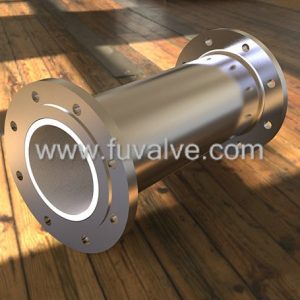

End Connection | Flange End, Butt Welding End, EN1092-1, DIN 2501, ASME B16.5 |

Typical Applications

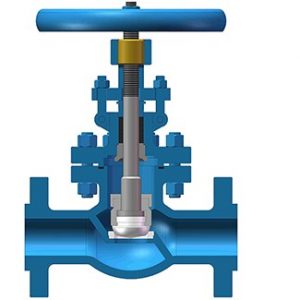

For metal seated globe valves,metal seat and disc sealing face is easily to get damaged if medium is corrosive or abrasive. Pressure Seal Ceramic globe valves are developed by FUVALVE to solve these corrosion and abrasion problems in high pressure applications. Pressure seal bonnet Ceramic globe valves are widely used in many severe high pressure applications, such as sea water, corrosive slurry, ect.

Product type

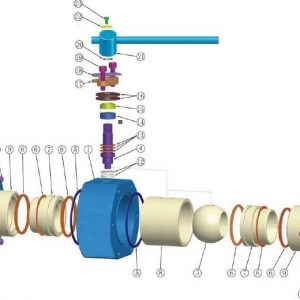

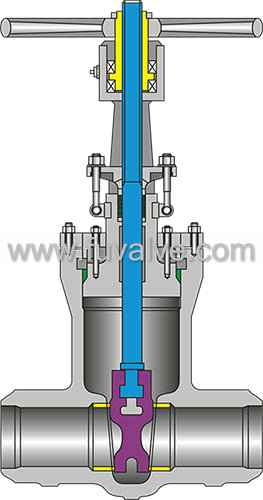

Pressure seal bonnet ceramic globe valves have many body structures for customers as below:

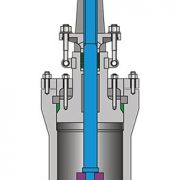

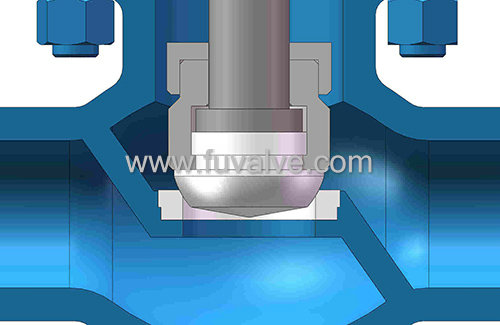

Straight pattern, angle pattern, Y pattern, forged body. These structures are all available for FUVALVE pressure seal ceramic globe valves. Rising Stem with precision threads are suitable for horizontal installation. Variable ceramic trim, including ZrO2 ceramics, Al2O3 ceramics, silicon nitride, tungsten carbide ,which make sure that pressure seal ceramic globe valves have excellent abrasion resistance and corrosion resistance. Spherical seat face and conical ceramic disc ensure that pressure seal ceramic globe valves are zero leakage.

Temperature range

Depends on the material used for pressure seal bonnet ceramic globe valves, normal working temperature is -29~250 degree.

Valve tightness

The disc and seat sealing face are well polished so that all pressure seal ceramic globe valves have tight shut off properties. The leakage class is up to Class VI.

Design Standards

Valve body design: BS 1868

Face-to-Face Dimension: ASME B16.10

Buttweld End: ASME B16.25

Flange Ends: ASME B16.5, EN 1092-1