2” ceramic ball valve for one of our machines.

Operating conditions:

– water at 60°C

-Working pressure 4bar

– presence of glass fiber dust.

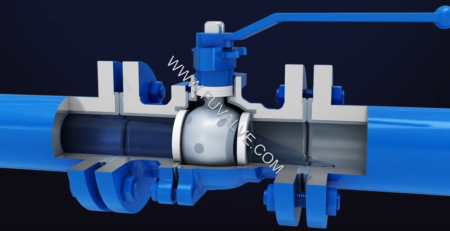

Pneumatic Ceramic Ball Valve

Specification:

| Type | Pneumatic Ceramic Ball Valve |

| Size | DN15-DN200(1/2”-8”) |

| Pressure Rating | PN10,PN16,PN25,PN40,CL150,CL300,JIS10K, JIS 20K |

| Body Material | WCB, A105, SS304,SS316,SS316L |

| Trim Material | ZrO2, 99% Al2O3,99.7%Al2O3,SSIC, STC, Si3N4 |

| Actuation | Pneumatic Actuator |

Pneumatic ceramic ball valves have been widely used in all kinds of extreme corrosive and abrasive applications, such as Silicon Powder,Alumina Powder,Dry Coal Powder,Limestone Slurry,Gypsum Slurry,Plaster,Fly Ash,Mining Ore,Coal Powder Injection,Metallurgical dust,Thermal Power plant FGD lime slurry,Petroleum Solid Catalyst pneumatic conveying system ,TiO2 suspension with sulfuric acid,Ammonia solution with powder,Hydrochloric Acid,Liquid Chlorine,Bulk Material pneumatic conveying system, etc.

Typical Applications:

In many corrosive or/and abrasive applications, PTFE or PFA lined ball valves and metal seated ball valves are used, but limited to the material, these PTFE or PFA lined ball valves and metal seated valves cannot last for a long time due to severe abrasion and corrosion. Ceramic ball valve have excellent performance and much longer life time than soft seated and metal seated ball valves in most corrosive and abrasive applications. Some typical applications listed below (but not limited to these applications) where FUVALVE Ceramic ball valve have been widely used all over the world: Silicon Powder,Alumina Powder,Dry Coal Powder,Limestone Slurry,Gypsum Slurry,Plaster,Fly Ash,Mining Ore,Coal Powder Injection,Metallurgical dust,Thermal Power plant FGD,Petroleum Solid Catalyst,TiO2 suspension with sulfuric acid,Ammonia solution with powder,Hydrochloric Acid,Liquid Chlorine,Bulk Material.

-400x231.jpg)