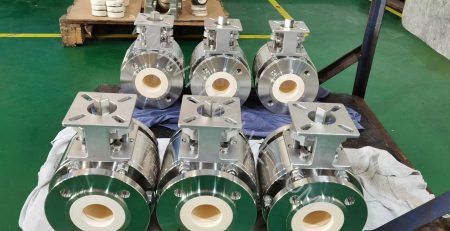

Ceramic lined C-type ball valve delivered to France user for Gravity Discharge application as below:

Fluid : Crushed wood + dry biomass 0-80 mm + small aluminum metal parts + pieces of glass

Transport speed : 30 to 50 meter per second, pneumatic

Pressure : 5 bar

Temperature : ambiant

No corrosive composition but pneumatic transport so very abrasive.

Product Characteristics

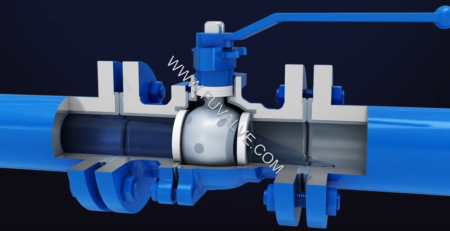

The C-type Ceramic Ball Valve with one or two-stage structure, single seat and no valve chamber. It has the properties of wear resistance, erosion resistance, high temperature resistance and crushing resistance.

Due to the straight-through design, when the valve is opened, there is no blocking element in valve chamber. And the surface of flow passage in C-ball has no rib, so there will be no sticking or blocking. When the valve closed, there is no material detention zone in valve chamber, which avoid material crystallization turning on unable to open.

It has self- cleaning function. When the valve is opening, C-ball is tilted away from valve seat, and the fluid flushes sundries along the sealing surface totally. When the valve is closing, C-ball moves gradually relative to the valve seat, which can realize the shearing of the adhering sundries on the sealing pair to ensure the cleaning of the sealing pair, and the wear resistance of the solid C-type ceramic valve seat will not be damaged by intercepted objects.

Its actuator connection is through the bracket interface, which meets the IsO 5211 size standard, and can also be customized according to customers’ requirements.