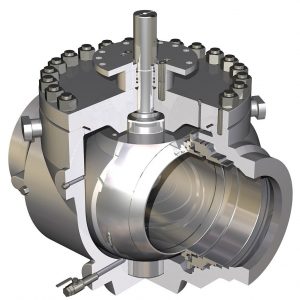

Cryogenic top entry ball Valve

- Description

- Inquiry

Cryogenic top entry ball Valve

A cryogenic top entry ball valve is made to specifically withstand temperatures below freezing point in industrial applications. It is generally made from stainless steel and bronze. It also comes with an extended bonnet for protection against extreme temperatures.

Products Introduction

The series of valve is FUVALVE which make improve combined with foreign advanced technology , for low temperature condition and special research and development , The top entry structure , can meet online service or replacement valve trim , special structural design , making dismounting more easy ,and further improve maintainability of valve . The use of advanced piston seal structure , and back pressure ring design , ensure the sealing reliable , when cavity pressure abnormal rises , can make pressure life on request of pressure relief direction by client . The unique loosed against measures and reasonable parts material configuration , further enhance the overall performance and service life of valve . This series of valve can be widely used for liquefied natural gas ( LNG ) , aerospace ,metallurgical and other areas in the low temperature conditions.

Design Specification

Design&Manufacturing:API 608;ASME B16.34;API 6D; BS 6364;MESC SPE 77/200;MSS SP-134; JB/T12625

End to End: API 6D;ASME B16.10 ;GB/T 12221;GB/T 17292

Flange Connection :ASME B16.5;ASME B16.25;HG;GB;JB;JIS;EN;DIN

Inspection & Test :API 6D; API 598/BS 6364; MESC SPE 77/200;MSS SP-134;JB/T 12622

Products Design Features

Full-bore or reduced bore design

Lip-seal stem sealing ring provides a primary seal with fugitive emission graphite packing design

Anti-blow out stem design ,with live load and the adjustable packing seal structure

Optional Metal or soft seal

Reliable seat auto pressure relief function,meet the upstream or downstream pressure relief

Fire prevention antistatic design

Heightening bonnet structure, preventing the effect of low temperature medium by packing, avoiding stem not scratched

Unique back pressure ring design ,to ensure the sealing performance

Height adjustable structure, to make the cold insulation space is not restricted

Trunnion or floating design

Low leakage design is available, detail technical requirements please refer to the low leakage sample.

Material:

| Body | Seat (metal sealing ) | Seat (soft sealing ) | stem |

| A182 F304/F304L;A351 CF3 A350 LF2;A352 LCB A350 LF3;A352 LCC A182 F316/F316L;A351 CF3M | A182 F316/F304+HF | KEL-F (PCTFE) | A182 F304 A182 F316 17-4PH UNS S20910 |

Note: Material is available upon request

Product Range

Nominal Size:1/2″~28″(DN15~700)

Pressure Rating:ANSI/ASME150Lb~1500Lb(PN16~250Mpa)

Suitable Temperature:-196~150 ℃

Operation:Manual ,Gear box, Electric,Pneumatic

-300x300.jpg)

-300x300.jpg)