Ceramic ball valve for carbon conveying application in steel mill

- Description

- Inquiry

Ceramic ball valve for carbon conveying application in steel mill

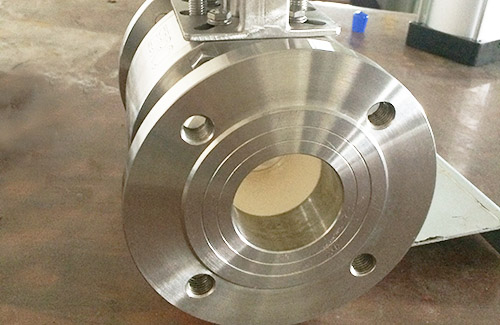

The application is purely for isolation of compressed air at 90 psi. The working temperatures are between 70 and 90 F. The reason for the ceramic ball is that the same pipe transports a stream of carbon at 160 lbs/minute. When the pipe is transporting carbon, the pressure will never exceed 90 psi, but will more than likely be around 30 psi. The line is isolated when the system is not in use for maintenance purposes. Therefore the valve will be actuated manually and will only be closed on maintenance turns. It will be normally open when the pipe is transporting carbon.

FUVALVE supplied more than 20pcs of DN50 half-lined ceramic ball valve to a well known steel mill in the USA,our products are excellent and success to solve the problem of abrasion to instead of the brand KITZ and TOYO valves.

Typical Applications:

In many corrosive or/and abrasive applications, PTFE or PFA lined ball valves and metal seated ball valves are used, but limited to the material, these PTFE or PFA lined ball valves and metal seated valves cannot last for a long time due to severe abrasion and corrosion. Ceramic ball valve have excellent performance and much longer life time than soft seated and metal seated ball valves in most corrosive and abrasive applications. Some typical applications listed below (but not limited to these applications) where FUVALVE Ceramic ball valve have been widely used all over the world: Silicon Powder,Alumina Powder,Dry Coal Powder,Limestone Slurry,Gypsum Slurry,Plaster,Fly Ash,Mining Ore,Coal Powder Injection,Metallurgical dust,Thermal Power plant FGD,Petroleum Solid Catalyst,TiO2 suspension with sulfuric acid,Ammonia solution with powder,Hydrochloric Acid,Liquid Chlorine,Bulk Material.

Related Products

Threaded end Ceramic Ball valve

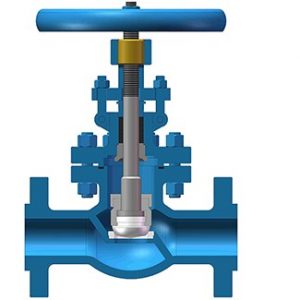

Bolted Bonnet Ceramic Globe Valves

Swing Type Ceramic Check Valves

Ceramic Sliding Disc Valve

Ceramic Lined Pipe Elbows

Ceramic-lined Butterfly Valve

Y Pattern Ceramic Globe Valves

Flue Gas Desulfurization ceramic ball valve

Threaded End Ceramic Ball valve

Threaded 3-pcs ceramic ball valve

Nominal Diameter:DN10-DN100

Nominal Pressure:1.0-6.4 MPa

Suitable Temperature:-20 to 280 Deg C

Ceramic Lined Y Diverters