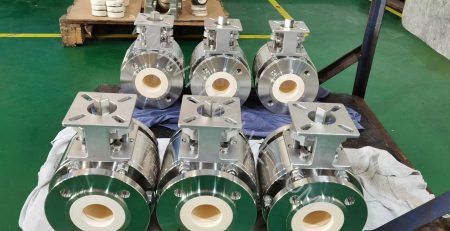

Ceramic lined pipe for wearing resistant delivered to our client

The following working conditions are some typical medium in which ceramic lined pipes have been proved to have good performance.

Coal powder

Fly ash

Mining slurry

Mining Slag

Coal washing

Strong acid slurry

Paper making Slurry

Specification:

Type | |

Size | DN15-DN400(1/2”-16”) |

Pressure Rating | PN10,PN16,PN25,PN40, PN63, PN100, PN160, CL150, CL300, CL600, CL900 |

Jacket Material | WCB, CF8, CF8M, CF3M, Hastelloy, Monel, Alloy 20, Titanium |

Lining Material | ZrO2 Ceramics, Al2O3 Ceramics, Tungsten Carbide, Si3N4, SSiC |

End Connection | Flange End, Butt Welding End, EN1092-1, DIN 2501, ASME B16.5 |

Datasheet of Technical ceramics

| Property | Units | Material | ||||

| 99.5% alumina | 99% alumina | 95% alumina | ZrO2 (Y-TZP) | ZrO2 (TTZ) | ||

| Density | g/cm3 | ≥3.85 | ≥3.80 | ≥3.60 | ≥5.95 | ≥5.72 |

| Water absorption | % | 0 | 0 | 0 | 0 | 0 |

| Hardness | HV | 1700 | 1700 | 1500 | 1300 | 900 |

| Flexural strength | Mpa | ≥379 | ≥338 | ≥320 | ≥1200 | ≥1200 |

| Compressive strength | Mpa | ≥2240 | ≥2240 | ≥2000 | ≥1990 | 1750 |

| Fracture toughness | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 11 |

| Max. service temperature | ºC | 1675 | 1600 | 1450 | 1000 | |

| CTE | 1×10 -6 /ºC | 6.5~8.0 | 6.2~8.0 | 5.0~8.0 | 8.0~9.5 | 10.2 |

| Thermal shock | T(ºC) | ≥250 | ≥200 | ≥220 | ≥300 | 350 |

| Thermal conductivity(25ºC) | W/m.k | 30 | 29 | 24 | 3 | 3 |

| Volume resistivity | ohm.cm | |||||

| 25ºC | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 | >1 x 10 11 | >1 x 10 11 | |

| 300ºC | 1 x 10 12 | 8 x 10 11 | 10 12 -10 13 | 1 x 10 10 | 1 x 10 10 | |

| 500ºC | 5 x 10 10 | 2 x 10 9 | 1 x 10 9 | 1 x 10 6 | 1 x 10 6 | |

| Insulation strength | KV/mm | 19 | 18 | 18 | 17 | 20 |

| Dielectric constant(1Mhz) | (E) | 9.7 | 9.5 | 9.5 | 29 | 28 |

-400x231.jpg)