Wear-resistant ball valve for catalyst

- Description

- Inquiry

Wear-resistant ball valve for catalyst

Products Introduction

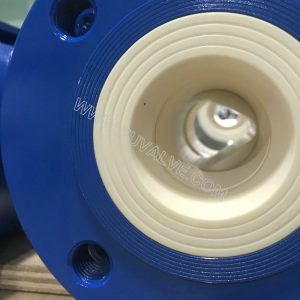

The wear-resistant ball valve for catalyst is a special valve designed for the catalyst process pipeline. The surface of the wear-resistant valve core of the wear-resistant ball valve is sprayed with a high-speed coating of tungsten carbide by a supersonic flame spraying process, and the valve seat sealing layer is too hard. The alloy is effective against the scouring and wear of the granular catalyst and prolongs the service life of the valve. The wear-resistant ball valve stem of the catalyst is made of high-strength stainless steel. The larger stem diameter improves the rigidity of the connection with the valve core, ensuring reliable and safe operation of the valve.

Production Design Specification

Design&Manufacture:ASME B16.34、API 608、GB/T 12237

End to End:ASME B16.10、GB/T 12221

Connection:ASME/ANSI B16.5;ASME B16.25;HG20615;GB;JB;JIS;BS;DIN

Inspection & Test:ASME B1 6.104;API 598;GB/T 26480;ISO 5208

Wear-resistant ball valve for catalyst

Product Features

Valve stem: anti-flying valve stem design, effectively avoiding the valve stuck in long-term high temperature conditions and possible site safety hazards. Super heat-resistant stainless steel + hardened to increase the tolerable torque.

Gasket: Type 304 +flexible graphite wound gasket, fire safety in accordance with API607

Pivot: The upper and lower shafts are supported and positioned. Under the action of medium pressure, the ball has no movement of the valve body in the axial direction, and the structure is simple and the reliability is strong.

Spring: The live-filled packing seal design ensures long-term reliability of the stem seal

Packing: stainless steel wire is combined with flexible graphite braided filler + flexible graphite ring. The braided packing ensures tight connection between the stem and the stuffing box, preventing the filler from being squeezed and keeping the stem aligned, which provides a reliable seal and longer use life.

- Inconel metal spring, which effectively compensates for the wear of the sealing surface caused by long-term high temperature use. The double spring dust-proof design overcomes the risk of the medium blocking the spring and eventually causing the spring to fail. 2. Seat scraper self-cleaning design, a variety of hardened coatings on the sealing surface can be selected HRC ≥ 65, strip seal to achieve zero leakage.

Combination Of Material

| Shell | Ball | Seat Ring | Stem |

| A105 F11/F22/F5 F304/F316/F321 B564 N06625 | A105+STL/N/WC/Ni F11/F22/F5+STL/N/WC/Ni F304/F316/F321+STL/N/WC/Ni B564 N06625+Ni | A105+STL/N/WC/Ni F11/F22/F5+STL/N/WC/Ni F304/F316/F321+STL/N/WC/Ni B564 N06625+Ni | F6a/17-4PH INCONEL X-718 F304/F316/F321+QPQ B564 N06625+QPQ |

Product Range

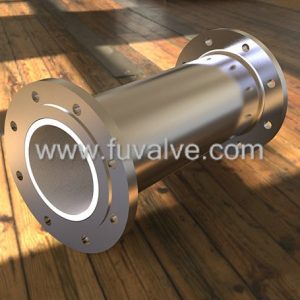

Nominal Size:1/2”-16”

Pressure Rating:150LB-1500LB(PN16~250Mpa)

Suitable Temperature:-29~538℃

Suitable medium:Catalyst + oil and gas

Operation:Hand wheel ,Gear box, Electric ,Pneumatic, Hydraulic.