Bellow seal anti-coking wear-resistant ball valve

- Description

- Inquiry

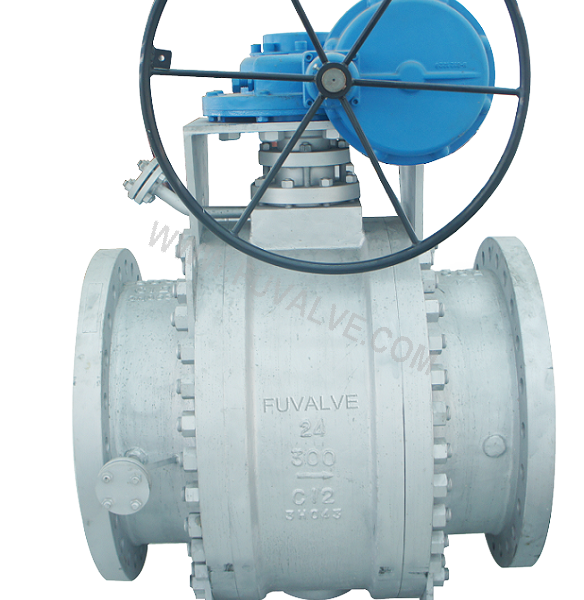

Bellow seal anti-coking wear-resistant ball valve

Products Introduction

The medium used for the high-temperature anti-coking wear-resistant ball valve in the coking unit is generally oil containing coke powder, vacuum residue and steam, and the working temperature is about 500 °C. Under this working condition, the valve must have the functions of corrosion resistance, wear resistance, erosion resistance, anti-coking and quick cutting under the conditions of easy coking and high temperature for a long time. The bellows anti-coking ball valve is provided with a bellows behind the valve seat. Due to the elastic loading structure of the bellows, it can ensure the close contact between the ball sealing surface and the sealing surface of the valve seat under normal closing conditions, and can effectively compensate at high temperature. The inner part is thermally expanded to avoid the jamming caused by high temperature, which effectively solves the harmful effects of the valve in the coking device against high temperature, coking, and erosion resistance. Its unique hard sealing surface has self-grinding effect, which makes it improve the sealing performance during the application of wear and erosion materials. It can work continuously under long-term conditions under severe working conditions, and its service life is several times longer than other valves.

Production Design Specification

Design&Manufacture:ASME B16.34、API 608、GB/T 12237

End to End :ASME B16.10、GB/T 12221

Connection :ASME/ANSI B16.5;ASME B16.25;HG20615;GB;JB;JIS;BS;DIN

Inspection & Test :ASME B16.104;API 598;GB/T 26480;ISO 5208

Bellow seal anti-coking wear-resistant ball valve

Product Features

Full-bore: The diameter of the sphere passage is the same as the diameter of the pipeline, the flow resistance is small, the circulation capacity is large, and the slag discharge is convenient.

Split ball valve: The valve seat at the inlet end of the anti-coking ball valve is a bellows valve seat, the outlet end is a metal valve seat that can slide in the valve body embedding groove, and a gasket is arranged between the valve body and the valve seat.

Adopting the structure of the scraping valve seat: In order to prevent the coke powder particles from entering the valve seat, the sealing surface of the valve seat is designed with a scraping structure with a sharp edge.

For the coke powder flushing condition ,the spherical and valve seat sealing surfaces adopt supersonic spraying technology, and the sealing surface hardness is improved by spraying different materials to improve the service life of erosion resistance and wear resistance.

Bellows seat seal design: In order to ensure the actual running time (with medium pressure), there is an initial contact pressure between the seat and the ball. The inlet end seat is made of a unique design of the bellows. When the temperature and pressure are alternating, Always give the seat a thrust so that it rests tightly against the ball. Under the combined action of the medium pressure, the seat is leaked to ANSI/ FCI Class V. At the same time, in order to prevent over pressure in the middle cavity, the valve seat compresses the bellows under the action of the pressure of the middle cavity, and automatically discharges the pressure into the passage to ensure safe and reliable operation of the valve. The bellows adopts Inconel 625 super alloy material to ensure the contact between the sealing surface of the ball and the sealing surface of the valve seat under normal closing conditions. It can effectively compensate the thermal expansion of the inner part under high temperature and avoid the jamming caused by high temperature.

Bellows steam purge design :This design can effectively prevent the medium from entering the bellows and cause the bellows to lose elasticity due to coking, and also prevent the valve leakage caused by the uneven pressing force of the valve seat due to vibration during the decoking process.

Valve chamber and stuffing box steam purging design: purging the valve chamber and stuffing box can prevent the coke from coking or depositing, effectively solving the problem that the valve inner part can not be opened due to the residue of the residue, and is effective protect the packing at the same time.

Live load packing design: the butterfly spring pre-tightening (ie live-load structure) is set between the packing compression stud and the packing compression nut. The high-temperature anti-coking ball valve can change the pre-tightening force of the combined packing in the temperature and stress alternating Continuity compensation is obtained to reduce the possibility of the packing leaking from the valve stem due to the sudden loss of pressure due to the preload.

Selection of actuators: The selection of high temperature anti-coking ball valve actuators has been considered. Over time, the expansion or contraction of the pipeline during coking or deposition or temperature exchange requires the actuator to have a large torque and determine the safety factor of more than 2 times.

Bellow seal anti-coking wear-resistant ball valve

Combination Of Material

| Shell | Ball | Seat Ring | Stem |

| A217 C12 F11/F22/F5 F304H/F316H/F321 | A182 F9+STL/N/WC/Ni F11/F22/F5+STL/N/WC/Ni F304H/F316H/F321+STL/N/WC/Ni | A182 F9+STL/N/WC/Ni F11/F22/F5+STL/N/WC/Ni F304H/F316H/F321+STL/N/WC/Ni | A638 660+STL/N/WC/Ni INCONEL X-718 F304H/F316H/F321+QPQ |

Bellow seal anti-coking wear-resistant ball valve

Product Range

Nominal Size:1/2”-16”

Pressure Rating:150LB-600LB(PN16~100Mpa)

Suitable Temperature:-29~538℃

Applicable medium: catalyst, slag reduction, circulating oil and gas mixture, containing coke powder

Operation:Hand wheel ,Gear box, Electric ,Pneumatic