Válvula de esfera cerâmica de resistência à erosão para transporte pneumático de pó de lítio

- Descrição

- Inquérito

Válvula de esfera cerâmica de resistência à erosão para transporte pneumático de pó de lítio (material de ânodo de bateria)

Como uma bateria de lítio de nova energia que recebe cada vez mais atenção. A capacidade de produção aumenta muito rapidamente. O material do ânodo da bateria de lítio é um material em pó de mícron. There is a tender that anode material will be tinier and tinier. It is easier to fly in the air because of tiny powder. Production environment is very severe and material recycle is very difficult while cost is high. Old original production method needs updating to suit modern current industry. Pneumatic conveying makes it possible to fulfill automatic production and unmanned workshop.

.jpg)

Advantages of pneumatic conveying of anode material for lithium battery production

1. Closed pipe transportation can achieve closed production

2. Dust is reduced, then production capacity increased

3. Reduce usage of workers. Currently, it is difficult to recruit workers every factory. Meanwhile, cost of workers increases every year, so it is a tender that machine will replace workers.

4. Reduce human factor and increase production efficiency.

5. Reduce human factor and raise production quality.

Válvula de esfera de cerâmica para transporte pneumático de pó de lítio

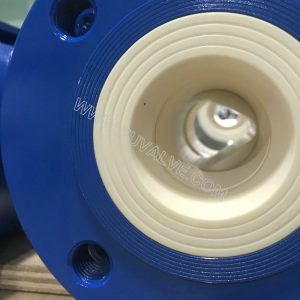

For pipe line of anode material conveying, metal valves will be abraded easily and metal impurities will pollute medium. Based on this condition, fully lined ceramic ball valve made by FUVALVE is the best choice. All part that will be in touch with medium are lined with ceramics, so medium will not be in touch with metal parts. Because hardness of ceramic is super high which will not be eroded by medium so that medium will be not be polluted by metal impurities.

Below are the válvulas de esfera de cerâmica we supplied to a battery anode material manufactory in May of 2018,now is still working excellent.

Datasheet of Technical ceramics

| Property | Units | Material | ||||

| 99.5% alumina | 99% alumina | 95% alumina | ZrO2 (Y-TZP) | ZrO2 (TTZ) | ||

| Densidade | g/cm3 | ≥3.85 | ≥3.80 | ≥3.60 | ≥5.95 | ≥5.72 |

| Water absorption | % | 0 | 0 | 0 | 0 | 0 |

| Hardness | HV | 1700 | 1700 | 1500 | 1300 | 900 |

| Flexural strength | Mpa | ≥379 | ≥338 | ≥320 | ≥1200 | ≥1200 |

| Compressive strength | Mpa | ≥2240 | ≥2240 | ≥2000 | ≥1990 | 1750 |

| Fracture toughness | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 11 |

| Max. service temperature | ºC | 1675 | 1600 | 1450 | 1000 | |

| CTE | 1×10 -6 /ºC | 6.5~8.0 | 6.2~8.0 | 5.0~8.0 | 8.0~9.5 | 10.2 |

| Thermal shock | T(ºC) | ≥250 | ≥200 | ≥220 | ≥300 | 350 |

| Thermal conductivity(25ºC) | W/m.k | 30 | 29 | 24 | 3 | 3 |

| Volume resistivity | ohm.cm | |||||

| 25ºC | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 | >1 x 10 11 | >1 x 10 11 | |

| 300ºC | 1 x 10 12 | 8 x 10 11 | 10 12 -10 13 | 1 x 10 10 | 1 x 10 10 | |

| 500ºC | 5 x 10 10 | 2 x 10 9 | 1 x 10 9 | 1 x 10 6 | 1 x 10 6 | |

| Insulation strength | KV/mm | 19 | 18 | 18 | 17 | 20 |

| Dielectric constant(1Mhz) | (E) | 9.7 | 9.5 | 9.5 | 29 | 28 |

Válvula de esfera cerâmica de resistência à erosão para transporte pneumático de pó de lítio

produtos relacionados

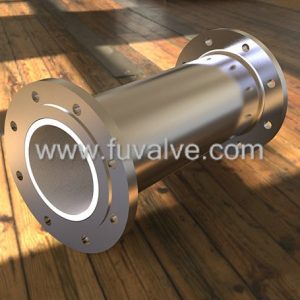

T-shirt revestidos de cerâmica para resistência à abrasão

Soluções de sistema de fluxo cerâmico

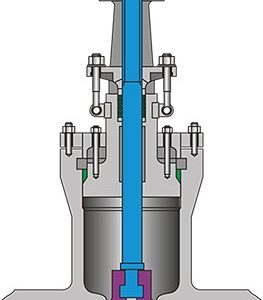

Válvulas globo de cerâmica com capô de vedação de pressão

Cotovelos de tubo revestido de cerâmica

Válvula de esfera cerâmica com extremidade roscada

Tubos revestidos de cerâmica para aplicações abrasivas

Válvulas de retenção de cerâmica do tipo oscilante

Válvula de esfera cerâmica V-port

Válvula de esfera de cerâmica com extremidade roscada

Válvula de esfera de cerâmica roscada de 3 peças

Diâmetro nominal:DN10-DN100

Pressão nominal:1.0-6.4 MPa

Temperatura Adequada:-20 para 280 Grau C

Válvula de esfera cerâmica para dessulfurização de gases de combustão

.jpg)