Wear-resistant Ceramic Eccentric Rotary Valve

- Descrição

- Inquérito

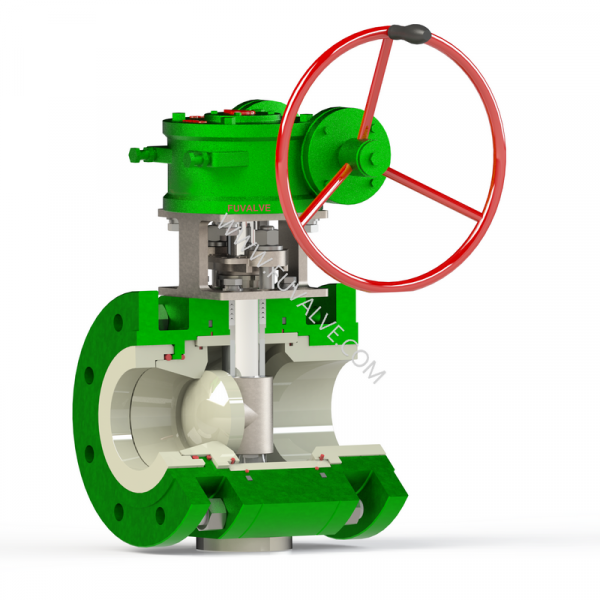

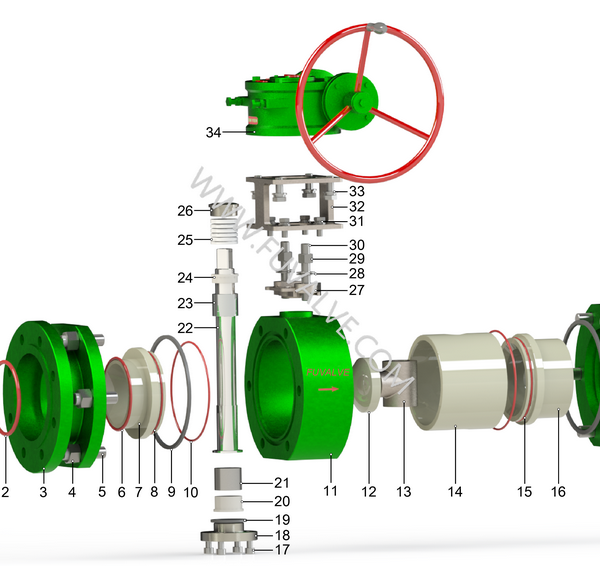

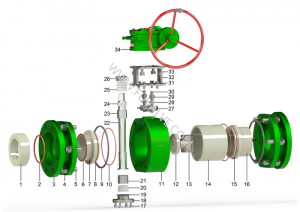

Wear-resistant Ceramic Eccentric Rotary Valve

FUVALVE Válvula rotativa excêntrica de cerâmica Série com design de duplo excêntrico, vedação de torque. Usando duplo excêntrico para produzir efeito de aperto de cunha de came para realizar vedação de torque. Ao fechar, a bola tipo C move-se gradualmente em relação ao assento, quanto mais apertada for a folga, e o grau de vazamento do selo rígido atinge VI. É uma vedação esférica típica. E, tem funções de corte e ajuste; Pode regular e controlar o estrangulamento em meio de lama com conteúdo sólido abrasivo, fluido fibroso, high viscosity and scale-prone slurry.

| Valve Size | DN25 | DN40 | DN50 | DN65 | DN80 | DN100 | DN125 | DN150 | DN200 | DN250 | DN300 | ||

| Rated Cv | 14 | 30 | 58 | 100 | 135 | 230 | 320 | 500 | 850 | 1300 | 1750 | ||

| FTF Length | 102 | 114 | 124 | 143 | 165 | 194 | 213 | 229 | 243 | 279 | 338 | ||

| Pressão nominal | PN10—PN160 ANSI150—2500 Others can be designed according to user requirements. | ||||||||||||

| Working temperature | -196℃—+100℃ -25℃—+950℃ -30℃—+160℃ -30℃—+180℃ -30℃—310℃ | ||||||||||||

| Padrão | GB HG DIN JIS ANSI Customized | ||||||||||||

| Material do corpo | WCB CF8 CF8M CF3 CF3M A105 304 316 316L TA2 | Cerâmica | Alumina ceramic, zirconia ceramic, silicon carbide, nitreto de silício | ||||||||||

| Flow characteristics | Open quickly, Equal percentage with positioner | ||||||||||||

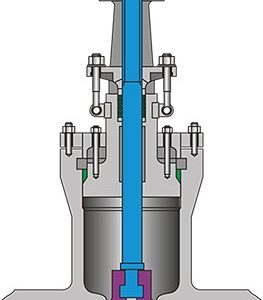

Working principle:

Ceramic eccentric rotary valve, the valve body adopts an integrated eccentric design, and the single valve seat through shaft design.It has the properties of corrosion resistance, wear resistance, resistência a altas temperaturas e antiesmagamento.

Structure description:

Devido ao design aerodinâmico da câmara da válvula, when the valve is opened, the valve chamber is open and there will be no blocking or clogging.When closed, there is no material retention area in the valve chamber to avoid material crystallization and cannot be opened.

The introduction of advanced ceramic processing technology, the use of special processes, the unique self-lubricating properties of ceramics; can ensure ultra-light opening and closing torque.

The actuator connection is through the bracket interface, which complies with the ISO5211 size standard.

When the sealing pair is opened, due to the self-cleaning and moisturizing properties of the ceramics, the fouling and adhesion on the sealing surface can be cut off during the opening process with shear effect.

When the sealing pair is closed, the wedging effect caused by the eccentricity can automatically compensate for the sealing of the valve; it can extend the service time of the sealing pair for leakage.