Pneumatic ceramic swing disc valve BZ643/ZKJ-B

- Description

- Inquiry

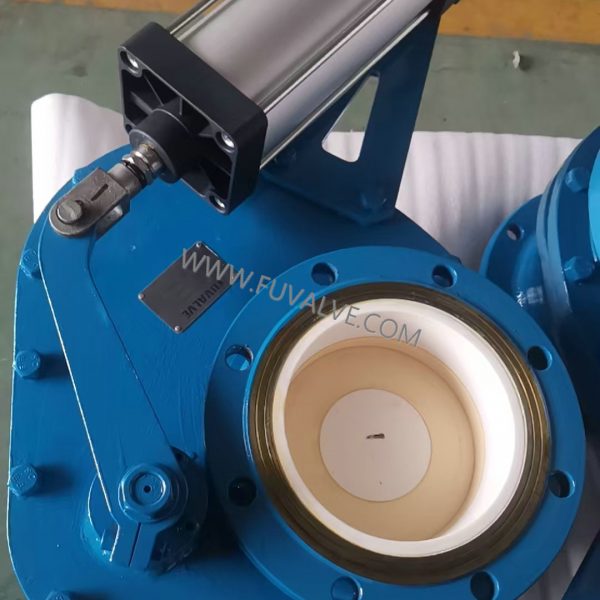

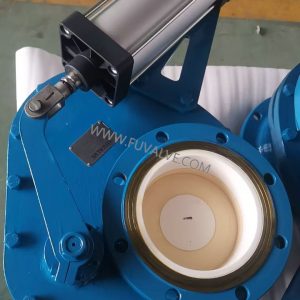

Pneumatic ceramic swing disc valve BZ643/ZKJ-B type

Product Overview

The rotary feed valve adopts structural ceramics as sealing vice (gate and seat are wear-resistant structural ceramics), which is resistant to scouring and abrasion. Rotary gate sealing structure,the opening and closing process of the gate spin, with polished 100 clean function, opening andclosing flexible.

Special drop bevel and large valve cavity design, completely solve the problem of ash accumulation, Pneumatic actuator piston rod does not write media contact, prolonging the service life of the actuator valve.

One-way seal when closed, suitable for sub-dry ash, pulverised coal, slurry, materials and other media transport. Commonly used in pneumatic conveying systemas a feed valve, instead of dome valve, no maintenance, long service life.

Pneumatic ceramic swing disc valve

Application specification

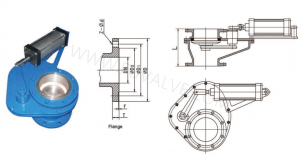

Nominal Diameter:PN200-DN300 [Reduced bore]

Nominal pressure 1.0MPa 150Lb

Applicable media: dry ash, pulverized coal, materials and media containing particles, etc.

Temperature: ≤280°C

1. Corrosion Resistant:

Cold Isostactic Pressing (CIP) and high-temperature sintering nanometer high-purity 99% Al2O3 and 99.7% Al2O3 (alumina) and ZrO2 (zirconia) ceramics will not interact with almost all organic and inorganic chemicals, nor contaminate process medium. Their physically and chemically stability against most acids, salts and alkalis will last for many years with little or no corrosive degradation, which make sure that Floating Ceramic ball valve have excellent performance in corrosive applications.

2. Abrasion Resistant:

The hardness of 99% alumina ceramics is about HRA88, harder than zirconia (about HRA85), solid tungsten carbide is about HRA 90,which is about 8 times harder than stainless steel. As valve trim, ceramic components make Floating Ceramic ball valve work well in the most severe abrasive conditions, such as pneumatic conveying to transport silicon powder, coal powder, Mg powder, etc.

3. Ceramic-to-Ceramic spherical seated:

The perfect fine grinded spherical seal between ceramic ball and seat ensure a Class VI shutoff. The anti-scratch design between disc and seat, which prevent sealing surface from being scratched by particles. The ceramic ball will not be stuck so ball will not be broken.

Temperature range

Depends on the material used for Plug type ceramic check valves, the normal working temperature is -29~250 degree.

Valve tightness

The disc and seat sealing face are well polished, all the ceramic globe valve have tight shut off properties. The leakage class is up to Class VI.