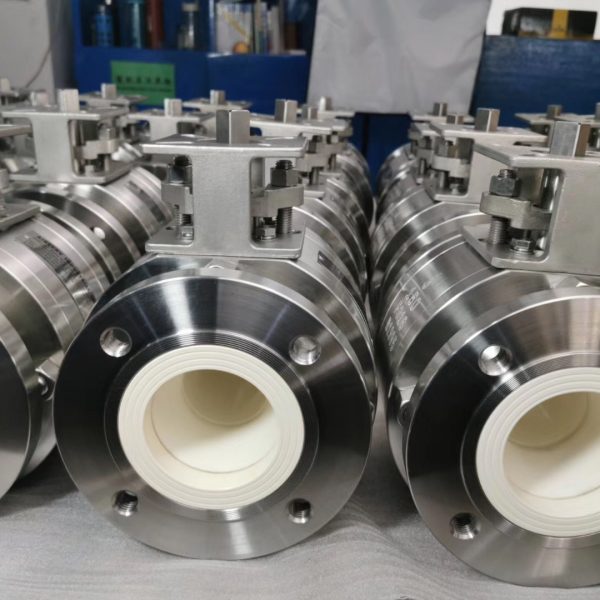

フローティングタイプセラミックボールバルブ

- 説明

- 問い合わせ

フローティングタイプセラミックボールバルブ

仕様:

タイプ | |

サイズ | DN15-DN100(1/2”-4”) |

圧力定格 | PN10、PN16、PN25、PN40、CL150、CL300、JIS10K, 彼は20Kです |

ボディ素材 | WCB, A105, SS304、SS316、SS316L |

トリム素材 | ZrO2, 99% Al2O3、99.7%Al2O3、SSIC, STC, Si3N4 |

接続を終了します | フランジ, ASME B16.5, EN1092-1, HE B2220 |

代表的なアプリケーション:

多くの腐食性または/および研磨性の用途, PTFEまたはPFAで裏打ちされたボールバルブと金属製のシートボールバルブが使用されます, ただし、素材に限定されます, これらのPTFEまたはPFAで裏打ちされたボールバルブおよび金属製のシートバルブは、激しい摩耗や腐食のために長期間使用できません。. Floating Ceramic ball valve have excellent performance and much longer life time than soft seated and metal seated ball valves in most corrosive and abrasive applications. 以下にリストされているいくつかの典型的なアプリケーション (ただし、これらのアプリケーションに限定されません) where FUVALVE Floating Ceramic ball valve have been widely used all over the world: シリコンパウダー,アルミナパウダー,ドライコールパウダー,石灰石スラリー,石膏スラリー,石膏,フライアッシュ,鉱石の採掘,石炭粉末注入,冶金ダスト,火力発電所FGD,石油固体触媒,硫酸を含むTiO2懸濁液,粉末のアンモニア溶液,塩酸,液体塩素,Bulk Material.

デザインの特徴:

1. Forged steel 3 piece body design:

FUVALVE Floating セラミックボールバルブ can fulfill existing connection requirements such as face-to-face dimensions and customers’ existing flange type.

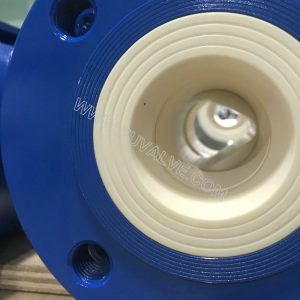

2. The wet parts are all ceramics—完全に裏打ちされたセラミック:

Ceramic components are assembled into forged metal body of Floating Ceramic ball valve which absorbs most physical loads and shock from piping lines.

3. Customized Actuation Types:

Actuator is connected to Floating Ceramic ball valve by a yoke that meets ISO 5211 specification including most pneumatic and electric actuators. The yoke is re-movable and easily modified to meet special requirements. Levers operated methods are also available for Floating Ceramic ball valve.

4. Corrosion Resistant:

Cold Isostactic Pressing (CIP) and high-temperature sintering nanometer high-purity 99% Al2O3 and 99.7% Al2O3 (alumina) and ZrO2 (zirconia) ceramics will not interact with almost all organic and inorganic chemicals, nor contaminate process medium. Their physically and chemically stability against most acids, salts and alkalis will last for many years with little or no corrosive degradation, which make sure that Floating Ceramic ball valve have excellent performance in corrosive applications.

5. Abrasion Resistant:

The hardness of 99% alumina ceramics is about HRA88, harder than zirconia (about HRA85), solid tungsten carbide is about HRA 90,which is about 8 times harder than stainless steel. As valve trim, ceramic components make Floating Ceramic ball valve work well in the most severe abrasive conditions, such as pneumatic conveying to transport silicon powder, coal powder, Mg powder, 等.

6. Ceramic-to-Ceramic spherical seated:

The perfect fine grinded spherical seal between ceramic ball and seat ensure a Class VI shutoff. The anti-scratch design between ball and seat, which prevent sealing surface from being scratched by particles. The ceramic ball will not be stuck so ball will not be broken.

7. V-port balls and Round-port balls:

FUVALVE offers all size of Floating Ceramic ball valve two different port: Round-port and V-Port balls. In general, the round-port ceramic ball valve is often used as an on-off valve. If precise and stable control performance is required in any corrosive and abrasive applications, V-port Floating Ceramic ball valve with equal percent characteristics may be the best choice.