Resistente all'usura Valvola a farfalla con sede pneumatica gonfiabile

- Descrizione

- Inchiesta

Resistente all'usura Valvola a farfalla con sede pneumatica gonfiabile

Applied to pulp, bulk powders, particelle, irregular solids, adhesive powders, gases and gas powders, the expansion butterfly valve ensures the reliability of system operation, extends valve life and reduces the impact of valve stoppage or replacement on material production.

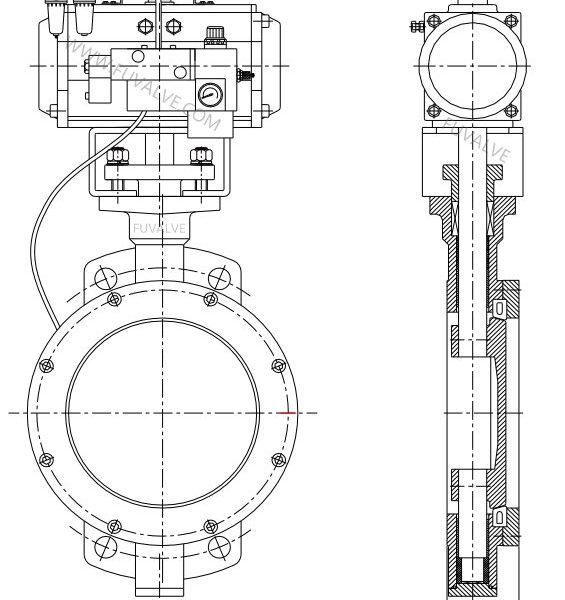

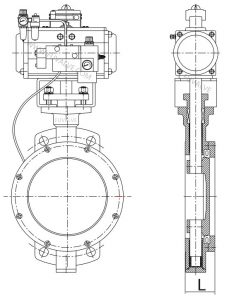

Pneumatic inflatable seated butterfly valve

product overview

Pneumatic inflatable seated butterfly valve (second generation) is an improved version of a new type of inflatable seated butterfly valve with an expandable and retractable valve seat. When the butterfly plate is closed in place, the rubber sealed valve seat is inflated and expanded under the pressure of the external air source, tightly adhering to the spherical surface of the butterfly plate circumference, thereby forming a reliable sealing ring and preventing the flow of materials in the pipeline. When the butterfly valve needs to be opened, the rubber sealed valve seat first quickly releases pressure, contracts, and the butterfly plate is released before starting to rotate, and the valve can be quickly opened into place. Eccentric sealing structure, the rubber sealing seat of the butterfly valve does not rub against the butterfly plate, and the mutual wear between the two is almost zero. The entire surface of the butterfly plate is sprayed with tungsten carbide or ceramic wear-resistant coating, providing higher stability and durability.

Suitable for handling highly abrasive media, it is an ideal valve for loose dry powder material conveying systems.

Suitable: Wear resistant, erosion resistant, replaceable seal, maximum temperature resistance of 250 ℃

Principio di funzionamento

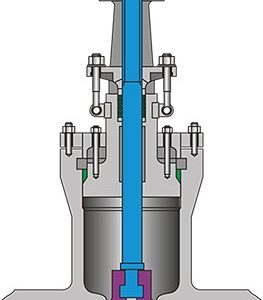

The pneumatic inflatable expansion seat butterfly valve (second generation) butterfly plate is an eccentric circular plate. During the opening and closing process of the valve, there is a gap of about 0.5mm between the butterfly plate and the rubber sealing ring, which allows the butterfly plate and the rubber sealing ring to move in a non-contact manner, thereby reducing friction and wear between the butterfly plate and the rubber sealing ring.

When the inflatable seated butterfly valve is in the closed state, the rubber sealing ring inflates and expands, tightly pressing against the spherical surface of the butterfly plate, forming a reliable sealing ring that prevents the flow of materials in the pipeline. When the inflatable seated butterfly valve is ready to open, the sealing ring first releases pressure and contracts. After the butterfly plate and sealing ring separate, the butterfly plate begins to rotate, and the valve can quickly open into place.

Pneumatic inflatable seated butterfly valve

Structural characteristics

1. Special rubber is used, which is wear-resistant and can withstand high temperatures up to 250 ℃, expanding the temperature range of use and making it more widely applicable.

2. The second-generation product features an inflatable seated type and eccentric sealing structure, which avoids mutual compression and friction between the valve seat, butterfly plate, and material, reducing the drawbacks of material crushing and valve wear.

The structure of the butterfly valve determines that after the valve is opened, the butterfly plate is always at the center of the pipeline and is washed away by the medium. Spraying ceramic or tungsten carbide wear-resistant coating on the entire surface of the butterfly plate can improve its erosion resistance.

4. The butterfly valve opens and closes under low friction conditions, significantly reducing the valve opening and closing torque. The operating torque is reduced by about 40% compared to traditional butterfly valves, and smaller actuators can be configured to reduce air consumption.

5 integrated pneumatic valve blocks ensure the stability and accuracy of valve opening and closing under high-frequency operating conditions, while reducing the overall size of the valve and simplifying on-site installation and maintenance.

6. The clamp connection method complies with GB/T9113, JB/T82.1, HG/T20592ASME/ANSIB16.5a standards. The valve is lightweight and easy to install and maintain.