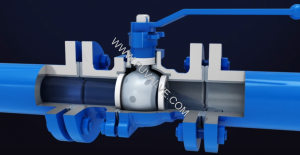

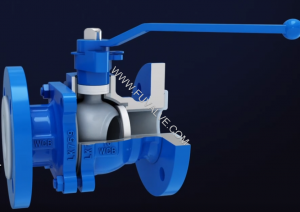

High-performance fluorine-lined ball valve, conçu selon 12237 SP MSS, est principalement utilisé pour contrôler l'activation et la désactivation des matériaux de pipeline. Il présente les avantages d'une faible résistance à l'écoulement, structure simple, performances d'étanchéité fiables, et ouverture et fermeture rapides. Les produits sont largement utilisés dans le pétrole, industrie chimique, Traitement des minéraux, chlore-alcali, pharmaceutical and other fields.It is suitable for high-performance media of acid-base salts with temperatures ranging from -29°C to 180°C.

Vanne à boisseau sphérique fluorée haute performance

This series of ball valves has the following structural characteristics

1. Anti-crystallization design with less accumulation of materials: imported fluorine materials are used in the lining of the valve, which has good corrosion resistance and better wear resistance. The valve body design is compact and the gap is small to minimize the accumulation of materials and prevent the accumulation from crystallizing and destroying the seal.

2. Anti-fly-out valve stem design: The valve body and the ball club are made of integrated castings, and the surface is provided with through holes and dovetail grooves to combine the lining layer with the metal parts. When the valve cavity is abnormally boosted, the valve stem will not fly out.

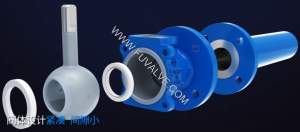

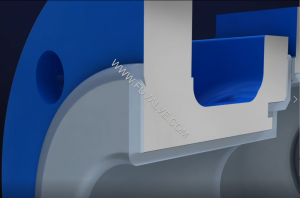

3. Sealing structure of the valve body and the valve cover boss: The valve body and valve cover are equipped with a sealing boss and dovetail groove structure to prevent the lining from falling off and effectively prevent leakage between the valve bodies.

4. U-shaped energy storage self-compensation design of valve seat: The sealing seat of the valve body and valve cover is provided with a U-shaped groove. Through the sealing preload of the valve body and valve cover, the sealing seat absorbs the compression force. When the valve is used for a long time, the sealing surface of the valve body and the valve cover will wear out. At this time, the sealing seat releases the preload force, which can effectively compensate for the sealing surface and ensure the sealing effect of the valve.

Product design specifications:

Norme de conception: HG/T 3704

Longueur de la structure: ASME B16.10, Go/T 12221.

Flange standard: ASME B16.5, Go/T 9113, HG20615, HG20592 main material: carbon steel, acier inoxydable, acier allié

Matériau de doublure: APF, FEP

Test de pression: API 598, GB/T13927, JB/T9092

Diamètre nominal: 1/2”-12″, DN15~DN300

Plage de pression: Classe 150 ~ 300, PN6~PN40