Válvula de bola de cerámica tipo flotante

- Descripción

- Investigación

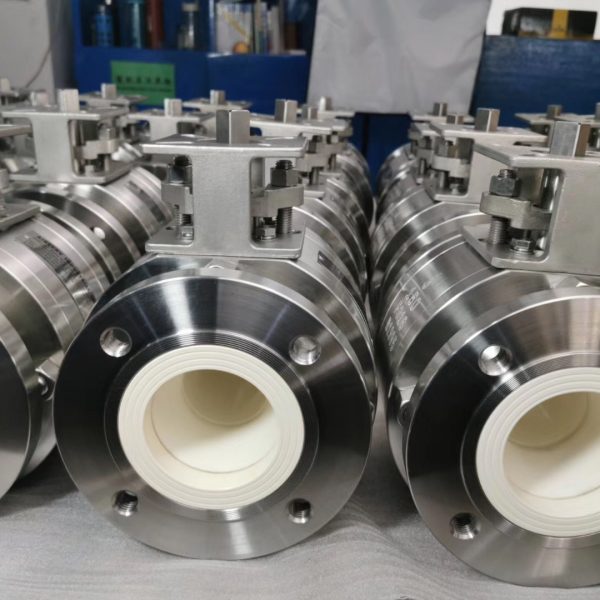

Válvula de bola de cerámica tipo flotante

Especificación:

Tipo | |

Talla | DN15-DN100(1/2”-4”) |

La calificación de presión | PN10, PN16, PN25, PN40, CL150, CL300, JIS10K, JIS 20K |

Cuerpo material | WCB, A105, SS304, SS316, SS316L |

Material de acabado | ZrO2, 99% Al2O3,99.7% Al2O3, SSIC, STC, Si3N4 |

Conexión final | Brida, ASME B16.5, EN1092-1, JIS B2220 |

Aplicaciones Típicas:

En muchas aplicaciones corrosivas y / o abrasivas, Se utilizan válvulas de bola revestidas de PTFE o PFA y válvulas de bola con asiento metálico, pero limitado al material, Estas válvulas de bola revestidas de PTFE o PFA y válvulas de asiento metálico no pueden durar mucho tiempo debido a la abrasión y la corrosión severas.. Floating Ceramic ball valve have excellent performance and much longer life time than soft seated and metal seated ball valves in most corrosive and abrasive applications. Algunas aplicaciones típicas enumeradas a continuación (pero no limitado a estas aplicaciones) where FUVALVE Floating Ceramic ball valve have been widely used all over the world: Polvo de silicio,Polvo de alúmina,Polvo de carbón seco,Lechada de piedra caliza,Lechada de yeso,Yeso,Ceniza voladora,Mineral minero,Inyección de polvo de carbón,Polvo metalúrgico,Central Térmica FGD,Catalizador sólido de petróleo,Suspensión de TiO2 con ácido sulfúrico,Solución de amoniaco con polvo,Ácido clorhídrico,Cloro liquido,Bulk Material.

Caracteristicas de diseño:

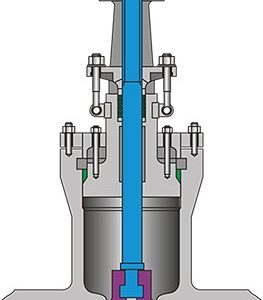

1. Forged steel 3 piece body design:

FUVALVE Floating Válvula de bola de cerámica can fulfill existing connection requirements such as face-to-face dimensions and customers’ existing flange type.

2. The wet parts are all ceramics—Cerámica totalmente forrada:

Ceramic components are assembled into forged metal body of Floating Ceramic ball valve which absorbs most physical loads and shock from piping lines.

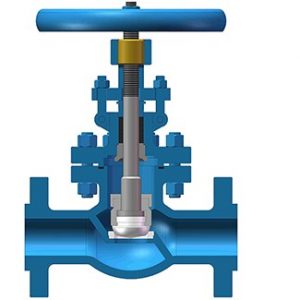

3. Customized Actuation Types:

Actuator is connected to Floating Ceramic ball valve by a yoke that meets ISO 5211 specification including most pneumatic and electric actuators. The yoke is re-movable and easily modified to meet special requirements. Levers operated methods are also available for Floating Ceramic ball valve.

4. Corrosion Resistant:

Cold Isostactic Pressing (CIP) and high-temperature sintering nanometer high-purity 99% Al2O3 and 99.7% Al2O3 (alúmina) and ZrO2 (zirconia) ceramics will not interact with almost all organic and inorganic chemicals, nor contaminate process medium. Their physically and chemically stability against most acids, salts and alkalis will last for many years with little or no corrosive degradation, which make sure that Floating Ceramic ball valve have excellent performance in corrosive applications.

5. Abrasion Resistant:

The hardness of 99% alumina ceramics is about HRA88, harder than zirconia (about HRA85), solid tungsten carbide is about HRA 90,which is about 8 times harder than stainless steel. As valve trim, ceramic components make Floating Ceramic ball valve work well in the most severe abrasive conditions, such as pneumatic conveying to transport silicon powder, coal powder, Mg powder, etc.

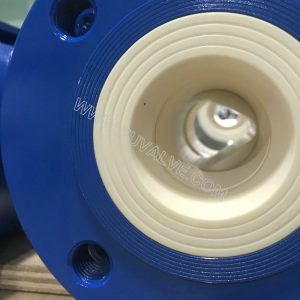

6. Ceramic-to-Ceramic spherical seated:

The perfect fine grinded spherical seal between ceramic ball and seat ensure a Class VI shutoff. The anti-scratch design between ball and seat, which prevent sealing surface from being scratched by particles. The ceramic ball will not be stuck so ball will not be broken.

7. V-port balls and Round-port balls:

FUVALVE offers all size of Floating Ceramic ball valve two different port: Round-port and V-Port balls. In general, the round-port ceramic ball valve is often used as an on-off valve. If precise and stable control performance is required in any corrosive and abrasive applications, V-port Floating Ceramic ball valve with equal percent characteristics may be the best choice.