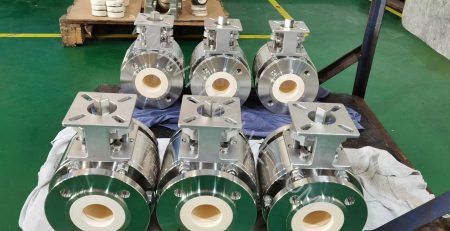

衬氟蝶阀使用手册

Lined valves and pipe fittings are applied quickly in the oil, 印染, 化学工业与现代工业的飞速发展.

作为项目的首选,引起了工程设计和公司的高度重视 , 在市场上具有巨大的潜力.

衬里阀具有切换和调节的双重功能, 在不影响流量的情况下,可以流畅地控制开闭,以确保流量的连续性 . Open slowly to reduce the instantaneous pressure impact on the instrument , like as add one more damper to increase service life of the valve greatly. Lined valve is specialized in control the strong corrosive medium , Body cavity will be covered by kinds of fluorine with good strength and corrosion resistance and suitable for different working temperature , 管道

Lined valve price is more expensive and work in critical environment with harmful chemical or strong corrosive acid-alkali or organic solvent, If use improper , it will cause big economy losing and serious consequence . Proper use and maintain lined valve can help to prolong service life and avoid any accident happen, ensure the pipeline work well . 所以, Following points should be noted :

1, Read carefully the production instruction before use.

2, Use according the specified pressure ,temperature and applicable medium of the range of the nameplate and manual

3,When use the valve to prevent too big stress caused due to temperature change.Minimize the temperature and add the U type compensator between the valve.

4,It is necessary to take measure to remove and limit the decomposable factor of unstable medium as the unstable and decomposable medium ( which will lead the volume expanded and caused working pressure increased abnormally ) effect the valve damage and leakage, It is forbidden to switch lined valve by lever , and note that the lined valve open-close indication of location and limit device, don’t inflict the strength toclose to prevent premature damage of fluorine of sealing face when open and close on the right position

5, It is necessary to take measure to remove and limit the decomposable factor of unstable medium as the unstable and decomposable medium ( which will lead the volume expanded and caused working pressure increased abnormally ) effect the valve damage and leakage,

6, It is forbidden to change the packing under the pressure when the lined valve apply in the toxic , flammable , explosive and strong corrosive medium. Although the lined valve with upper sealing function design , it still do not suggest to change the packing under pressure.

7, For the pipeline with pyrophoricity medium , should take measure to keep ambient temperature and working temperature not exceed auto-ignition point , prevent the risk caused from sunshine and outer fire.

8, It should take measure to eliminate if the pipeline with the long and severe vibration , and avoid the lined valve damaged .

9, The fluorine sealing face is soft and easily damaged by the crystallizing mediums, solid granule during the lined valve use, should maintain and change the sealing part

timely after the discovery

10, It should change the sealing parts timely if the sealing face damaged prematurely when the part-apply as adjust the flow rate during lined valve use.

11, Usually the flange of lined valve without gasket, it can screw up the nut of middle flange to remove the leakage if the middle flange caused leakage. We should maintain the sealing face or add the middle flange gasket to eliminate the leakage if the middle flange damaged.

12, Unscrew the bonnet nut properly if the lever and hand wheel is stiff or couldn’t switch the lined valve, If the movement is still ,maybe the bonnet skewed and should adjust the bonnet correctly.

After adjust and unscrew the bonnet but still can’t switch lined valve, should disassemble and inspect , clean until problem solved.

When disassemble the lined valve , should note the pipeline medium of lined valve , whether it is used or new . The working operator should wear the protective mask and gum glove, protective clothes and operate according to instruction if the medium with toxic,

Inflammable, explosive to avoid the accident during the disassembly .