Pneumatic pinch valve(GJ841X-Ⅱ-6L)

- Description

- Inquiry

Pneumatic pinch valve(GJ841X-Ⅱ-6L)

Working principle:

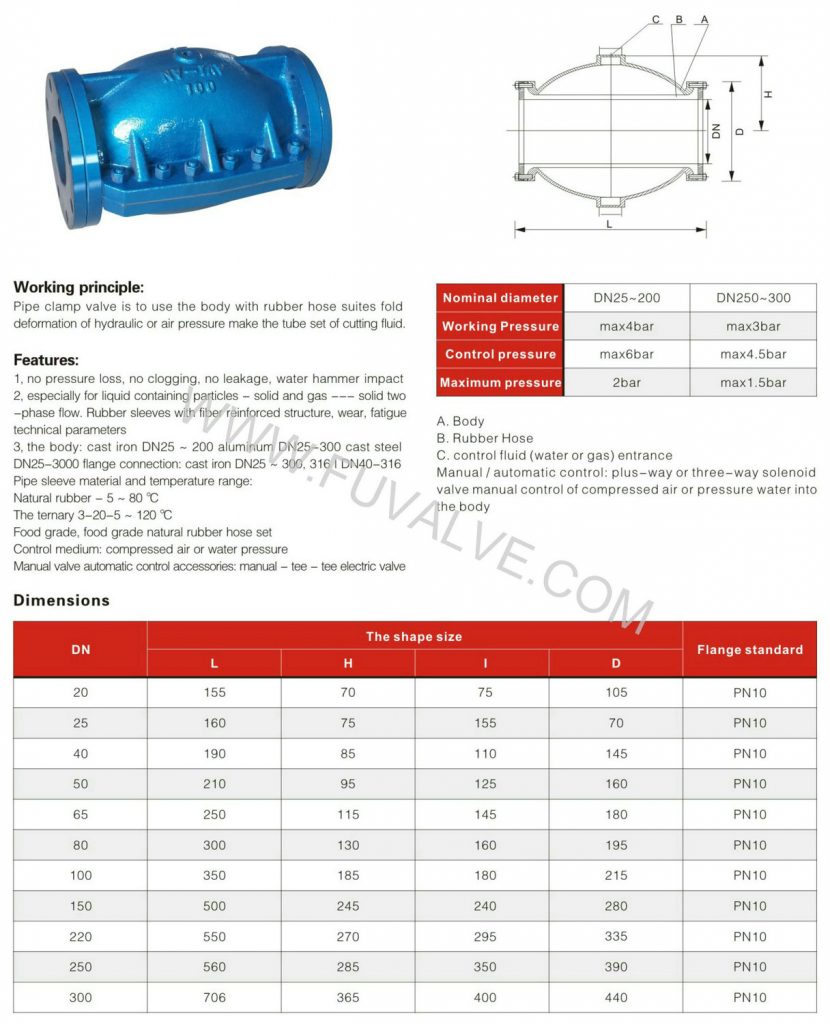

Pipe clamp valve is to use the body with rubber hose suites fold deformation of hydraulic or air pressure make the tube set of cutting fluid.

Features:

1. no pressure loss,no clogging,no leakage,water hammer impact

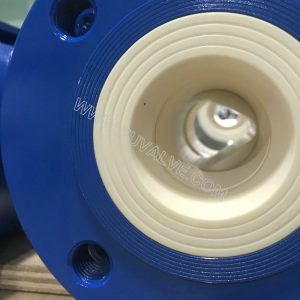

2. especially for liquid containing particles – solid and gas — solid two-phase flow.Rubber sleeves with fiber reinforced structure,wear,fatigue technical parameters

3. the body: cast iron DN25~200 aluminum DN25-300 cast steel DN25-3000 flange connection: cast iron DN25~300,3161DN40-316 Pipe sleeve material and temperature range:

Natural rubber – 5 ~80 ℃

The ternary 3-20-5~120 ℃

Food grade,food grade natural rubber hose set

Control medium: compressed air or water pressure

Manual valve automatic control accessories: manual – tee – tee electric valve

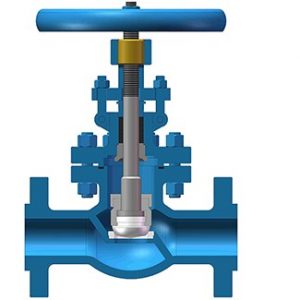

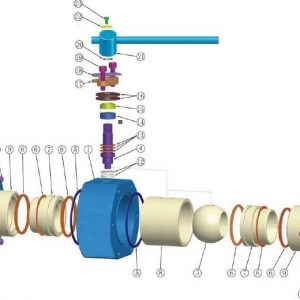

A.Body

B.Rubber Hose

c.control fluid(water or gas)entrance

Manual/automatic control:plus-way or three-way solenoid valve manual control of compressed air or pressure water into the body.

Pneumatic pinch valve(GJ841X-Ⅱ-6L)

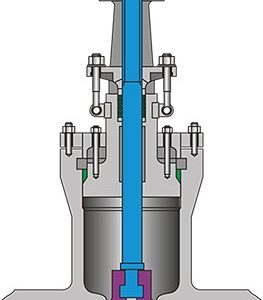

is a valve comprising a flexible tube, either exposed or enclosed in a body. The tube is pinched to close mechanically or by application of fluid pressure in the body.

The “working” element of a pinch valve, also known as a clamp valve, is an elastomeric tube or sleeve which can be squeezed at its mid-section by some mechanical system until ultimately the tube walls are pinched or clamped together producing full closure of the flow path.

In its simplest form it can consist merely of a length of elastomeric tube fitted with a pinch bar mechanism incorporating a closure stop to prevent over-pinching of the tube. More usually the moulded rubber tube is housed in a metal body which also incorporates the pinching mechanism. This can be a simple screw-operated mechanism, where the pinch is applied only to one side of the tube, or a differential screw controlling two pinching mechanisms working in vertical opposition. The latter produces lower-stress working of the tube.

Other types of pinch valves dispose with mechanical mechanisms entirely, the tube being squeezed shut by air or hydraulic pressure injected directly into the body of the valve.