Pinch valve

- Description

- Inquiry

Pinch valve

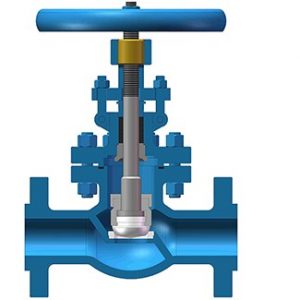

1. the main structures:

The valve consists of valve body,valve rod,rubber sleeve size,plate, rod,a bracket.a hand wheel and other parts.

2.the principle of work:

When turn the handwheel clockwise,the size of the stem and is rotated to drive the upper and lower plates to compress the rubber sleeve to a close, and will be open.This plate in tension rod between the up and down reciprocating movement to complete the valve opening and closing work.

3.the matters needing attention:

Because the rubber sleeve bearing force is small,so in the opening and closing,the operating personnel rotation handwheel was appropriate as long as the conflict,to open and close the pole.Do not try to and more support, disable other tools to open and close.

4.installation and maintenance:

The valve in the pipe installation without any restrictions,the flow direction of medium.

The valve maintenance cost is low,there is no need regular replacement of valve seat,sealing filler,a sealing ring or a telescopic tube.Tube is a pipe clamp valve only need to replace parts,once the replacement of the hose, valve as the new valve.This valve requires little other parts inventory.

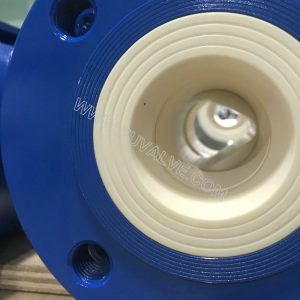

Pinch valve is a valve comprising a flexible tube, either exposed or enclosed in a body. The tube is pinched to close mechanically or by application of fluid pressure in the body.

The “working” element of a pinch valve, also known as a clamp valve, is an elastomeric tube or sleeve which can be squeezed at its mid-section by some mechanical system until ultimately the tube walls are pinched or clamped together producing full closure of the flow path.

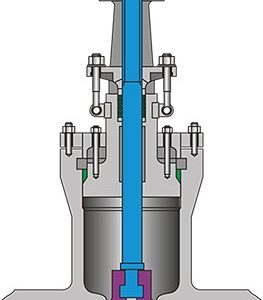

In its simplest form it can consist merely of a length of elastomeric tube fitted with a pinch bar mechanism incorporating a closure stop to prevent over-pinching of the tube. More usually the moulded rubber tube is housed in a metal body which also incorporates the pinching mechanism. This can be a simple screw-operated mechanism, where the pinch is applied only to one side of the tube, or a differential screw controlling two pinching mechanisms working in vertical opposition. The latter produces lower-stress working of the tube.

Other types of pinch valves dispose with mechanical mechanisms entirely, the tube being squeezed shut by air or hydraulic pressure injected directly into the body of the valve.