Low load type ventilation butterfly valve

- Description

- Inquiry

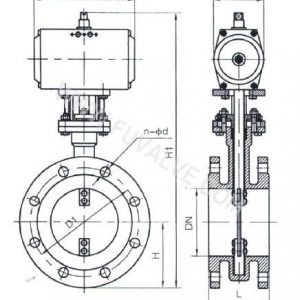

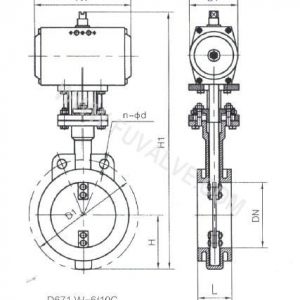

Low load type ventilation butterfly valve

The highest temperature up to 1000℃

Low load type ventilation butterfly valve is a kind of simple structure, installation space is small, light weight, low cost, has made economic practical control valve.This valve is suitable for large flow,low differential pressure,leakage level low gas, liquid and slurry shape and fluid line.But with all kinds of electric,pneumatic, actuator combined supporting the use of a combination of different performance of the valve,realize cutting, regulating function.The main medium:gas,flue gas, air and dust gas;The highest temperature to 1000℃;Product features:take rust die device ,can guarantee the long-term use of switch is quick,light.

High temperature butterfly valve with manual gear or supporting the use of pneumatic and electric actuators. And installing the heat sink to protect electric, pneumatic actuators, extend valve life.High temperature butterfly valve installed in the pipeline to accept the control signal automatic control or block. The valve in the closed position left a gap between the gate and valve to take, to ensure that thermal expansion will still function properly when used.Because of this valve is used specifically for RTO ( regenerative thermal incineration ) smoke and industrial kiln system to meet the furnace pressure automatic control and adjustment, it is also known as the flue butterfly valve or pressure relief valve in the furnace.

The pressure-temperature equal group of valve body is max. allowable working pressure expressed in gauge pressure under specified humidity. When temperature rises, the allowable working pressure will reduce. To enable the users to correctly choose the desired valve and avoid losses, we hereby list pressure- -temperature equal group of different materials as below according to the relevant stipulations of State Standard JB/T3595.