NH4NO3 solution used full lined ceramic butterfly valve

- Description

- Inquiry

NH4NO3 solution used full lined ceramic butterfly valve

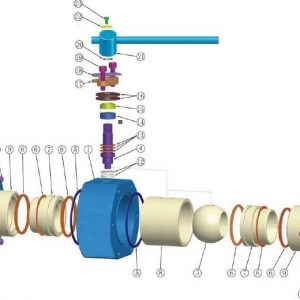

The Full lined ceramic butterfly valve for NH4NO3 solution with heating jacket for the medium of Ammonium nitrate NH4NO3 and molten alum NH4 Al(SO4)2. 12H2O which operating temperature is 128°C with pressure max 13 bar.The body and disc material requested 304L full lined ceramics.As the Ambient temperature is -28 deg C,there is steam a at 175 deg C for heating jacket.

NH4NO3 solution used full lined ceramic butterfly valve

Performance characteristics

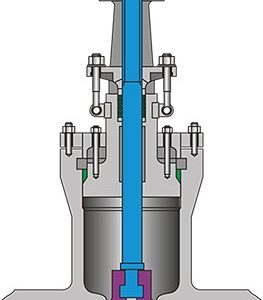

1. Ceramic butterfly valve butterfly sealing ring and valve seat are made of high-performance structural ceramic materials, eccentric butterfly in the valve opening and closing with the valve house sealing surface sharing, can reduce the sealing surface of the friction so as to extend the service life of the valve.

Pake ceramic sealing ring, valve seat and o-ring can be replaced as needed, the excellent performance of structural ceramics so that ceramic butterfly valves can be widely used in slurry, ash and other corrosion-resistant valve fittings. Abrasion and scouring resistance requirements of higher performance occasions.

Typical Applications:

For most mediums which contains solid particles, abrasion is a very troublesome problem for valves and pipe fittings. Butterfly valve is one of the most common valve types in pipelines. For the medium which contains abrasive particles, the service life of soft sealing and metal sealing butterfly valves will be very short. To solve this problem, FUVALVE developes ceramic butterfly valves to meet the requirements of high abrasive applications. For the medium contains both abrasive and corrosive, we will select suitable body materials for lug ceramic butterfly valves to avoid possible corrosion.

Mining slag

Coal washing

Ash Slurry

Suspension

Ash

Grain

Quartz Sand

Metallurgical dust

Ores

Granules

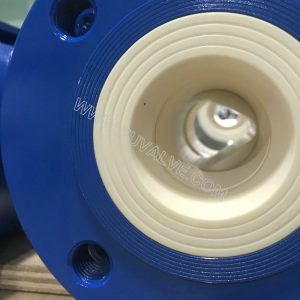

NH4NO3 solution used full lined ceramic butterfly valve .Typical properties of structural ceramic hard sealing valve include:

- Wear and corrosion resistance

The valve sealing ring, valve seat and inner lining are all made of Hi-performance structural ceramics with hardness of HRA87 or above. So structural ceramic ball valves can withstand the impact of Hi-speed liquids and hard grains, displaying excellent performance on wear and corrosion resistance. - Corrosion resistance

The valve sealing ring, valve seat and the inner lining are all made of High-performance structural ceramics. They have been examined by the Metal Research Institute of Chinese Academy of Sciences, showing that the structural ceramics have excellent corrosion-resistance, except to glass-liquor and hydrofluoric acid. - Long working life

The static pressure test showed no leakage after 10000 times opening-closing. - Wide-range of applications

Structural fully lined ceramic butterfly valve are applicable to various acid, alkaline or saline solutions, gaseous media, etc. Hard sealing ball valves can also be used in media with particles and fibers.