Erosion resistant ball valve

- Description

- Inquiry

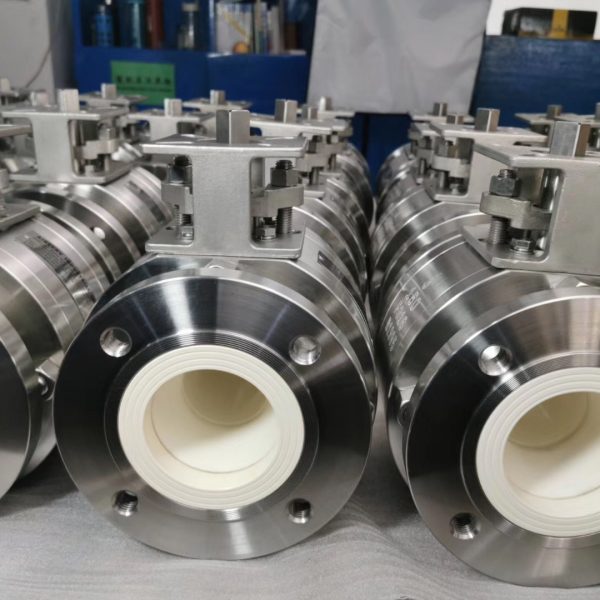

Properties of Ceramic lined Ball Valve

Typical properties of structural ceramic ball valve include:

- Wear and corrosion resistance

The valve ball, valve seat and inner lining are all made of Hi-performance structural ceramics with hardness of HRA87 or above. So structural ceramic ball valves can withstand the impact of Hi-speed liquids and hard grains, displaying excellent performance on wear and corrosion resistance. - Corrosion resistance

The valve ball, valve seat and the inner lining are all made of Hi-performance structural ceramics. They have been examined by the Metal Research Institute of Chinese Academy of Sciences, showing that the structural ceramics have excellent corrosion-resistance, except to glass-liquor and hydrofluoric acid. - Long working life

The static pressure test showed no leakage after 10000 times opening-closing. - Wide-range of applications

Structural ceramic ball valves are applicable to various acid, alkaline or saline solutions, gaseous media, etc. Hard sealing ball valves can also be used in media with particles and fibers.

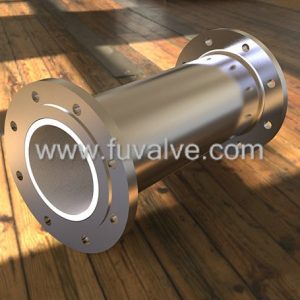

Erosion resistant ball valve,the ceramic lined ball valve

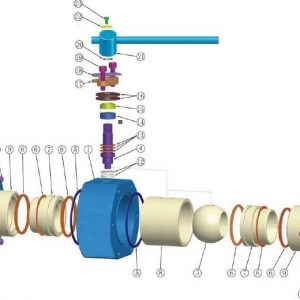

Design Features:

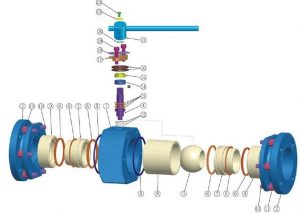

- Floating ball or trunnion ball

FUVALVE provide two basic structures for ceramic ball valves: Floating ball and trunnion ball. For 4” (DN100) and smaller,the valve has a floating ball, and for 5” (DN125) and larger sizes, trunnion mounted ball is provided.

For other main features of ceramic lined ball valve, please refer to ceramic floating ball valves and ceramic trunnion ball valves. Or contact us at sales@fuvalve.com for more detailed technical information of ceramic ball valves.

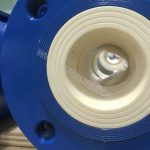

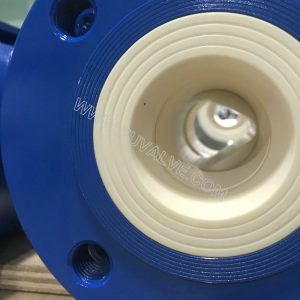

- The parts touching medium are all ceramics—Ceramic fully lined

Because the mediums are mostly high abrasive and corrosive, ceramic components are assembled into forged metal body of ceramic lined ball valves which absorbs most physical loads and shock from piping lines. The medium will not directly touch valve body, therefore no parts will be worn out or corroded by the aggressive medium.

- Bare stem valves, Pneumatic and electric control system

Generally ceramic ball valves are actuated by pneumatic actuators or electric actuators. Fuvalve has well trained technicians to assemble complete pneumatic and electric actuator onto valves. We can assemble all possible accessories to ceramic ball valves per customer’s requirements, such as pneumatic actuators, limit switch, electric-pneumatic petitioners, solenoid valves, filter and regulators, and smart electric actuators, etc.

Fuvalve can offer bare stem ceramic ball valves to customers, so that they can assemble their actuators onto valve by themselves. A yoke with ISO 5211 mounting pad is provided along with bare stem ceramic ball valves for easy installation.

Advantages of ceramic ball valve include hi-economy, long life (2~4 times of Titanium Valves), increase resistance to corrosion, high temperature, wear and erosion etc.. They are commonly used in transportation systems of various acid, alkaline or saline gases, solutions, high working temperature steams and slurry, in the lines of oil industry, metallurgy, paper making, power station, refinery, etc. ceramic ball valves are the ideal substitute for titanium and montel valves in corrosive environments. There are four types of driving performances, manual, pneumatic, pneumatic-spring return and electric. Various special valves can be designed on demand. Furthermore, various high wear-resistant, corrosion-resistant and high temperature-resistant ceramic components, hydraulic pressure sealing components can be provided as well.