CERAMIC GATE VALVE

- Description

- Inquiry

Best solutions to abrasionerosionhigh temperature conditions for unique durability due to structural ceramics sealing faced.

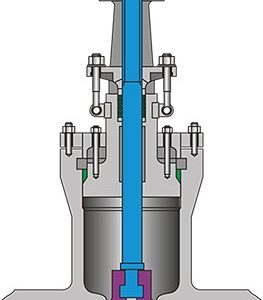

1.Bonnet designed to avoid packing box leak which the knife valve can not achieve.

2.Flow-into port small designed, but flow-out port big designed to avoid accumulation of coal remain and its block.

Suitable for two kinds of physical forms of medium transferring such as coal residue, slurry residue, mine slurry and sewage.

Nominal Dia:DN50-DN600(2″-24″)

Class:PN1.0-2.5MPa、ANSI CLASS 150LB

Specification:

Type | |

Size | DN25-DN400(1”-16”) |

Pressure Rating | PN10,PN16,PN25,PN40, CL150, CL300 |

Body Material | WCB, CF8 |

Trim Material | WCB+Al2O3 Ceramics, WCB+ZrO2 Ceramics, WCB+Solid Tungsten Carbide,WCB+Stellite |

End Connection | Flanged type, Wafer Type, EN1092-1, DIN 2501, ASME B16.5 |

Features:

Product type

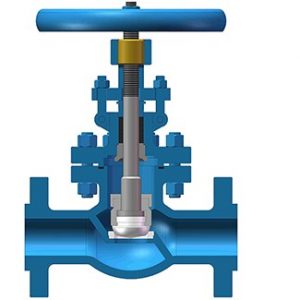

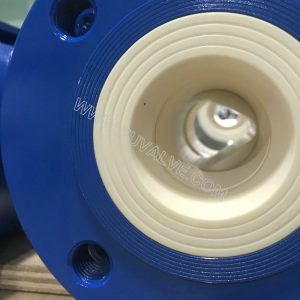

The Ceramic Gate Valve is ceramics-to-ceramics sealing, also named as parallel double disc valve, or ceramic double disc valve or ceramic double gate valve.

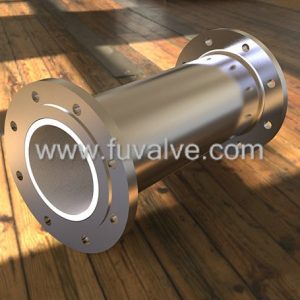

The standard end connection of ceramic gate valves is flanged type, but if the installation space is limited, wafer type is available.

Three piece bodies of Ceramic Gate Valves are very easy for assemble and reliable for maintenance.

Self-cleaning disc design allows disc to move freely and avoid being scratched by solid particles.

Temperature range

Usually working temperature of pneumatic conveying system is not so high, but under some conditions like economizer valves in coal fired power plant, the working temperature may be up to 450 ℃. Then special design of ceramics and packing material will be considered.

Detailed information about working temperature of our Ceramic Gate Valves, please contact us at sales@ceramic-valves.com.

Normal working temperature of Ceramic Gate Valves: -29 °C ~ +200 °C

High temperature design of Ceramic Gate Valves: -29 °C ~ +450 °C

Valve tightness

The tightness of valve is very important. FUVALVE has advanced ceramic processing technology and skilled technicians. All ceramic sealing faces of the Ceramic Double Disc Gate Valves are well ground and polished, which ensure Class V leakage as per FCI 70-2.

Other tightness rates upon request.

FUVALVE Ceramic Double Disc Gate Valves have much longer service life than the other similar products.

Design standards

Valve body ASME B16.34

Face-to-Face: Manufacturer’s Standard, customized length of Ceramic Double Disc Valves is available.

Valve Testing: API 598

The structure of FUVALVE Ceramic Double Disc Gate Valve is as the following exploded drawing.