Erosion resistance ceramic butterfly valve for fly ash

- Description

- Inquiry

Erosion resistance ceramic butterfly valve for fly ash

Currently the customer is using a Keystone model F990 with polyurethane seats and CF8M disc and are getting approx. 6 weeks life out of the valve.

The valve will be able to extend the life of the valve to approx. 12 months.

.jpg)

Specification:

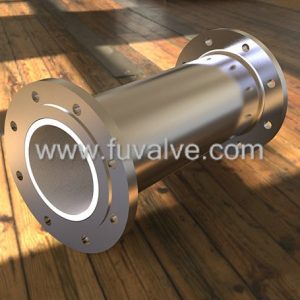

| Type | Ceramic Butterfly Valves |

| Size | DN50-DN400(2”-16”) |

| Pressure Rating | PN6, PN10,PN16, CL150 |

| Body Material | WCB, CF8, CF8M, CF3M,CN7M |

| Trim Material | 99% Al2O3 Ceramics, ZrO2 Ceramics, Si3N4, Solid Tungsten Carbide |

| End Connection | Lug Type,EN1092-1, DIN 2501, ASME B16.5 |

Erosion resistance ceramic butterfly valve for fly ash

Performance characteristics:

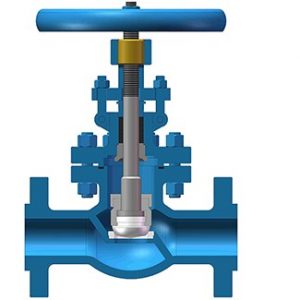

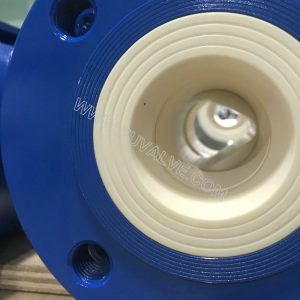

1. Ceramic butterfly valve butterfly sealing ring and valve seat are made of high-performance structural ceramic materials, eccentric butterfly in the valve opening and closing with the valve house sealing surface sharing, can reduce the sealing surface of the friction so as to extend the service life of the valve.

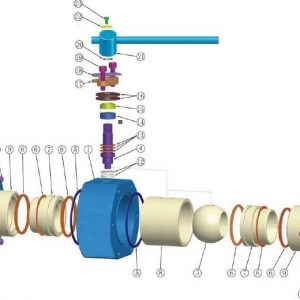

Pake ceramic sealing ring, valve seat and o-ring can be replaced as needed, the excellent performance of structural ceramics so that ceramic butterfly valves can be widely used in slurry, ash and other corrosion-resistant valve fittings. Abrasion and scouring resistance requirements of higher performance occasions.

Typical Applications:

For most mediums which contains solid particles, abrasion is a very troublesome problem for valves and pipe fittings. Butterfly valve is one of the most common valve types in pipelines. If working medium is abrasive, service life of both soft sealing and metal sealing butterfly valves is very short. To solve this problem, Fuvalve developes Lug type ceramic butterfly valves to meet the requirements of high abrasive applications. If working medium is both abrasive and corrosive, we can select suitable body materials for lug ceramic butterfly valves to avoid possible corrosion.

-Mining slag

– Coal washing

– Ash Slurry

– Suspension

– Fly ash

– Grain

– Quartz Sand

– Metallurgical dust

– Ores

– Granules

Design Features:

Product type

1.ceramic butterfly valves are light and easy to install.

- FUVALVE triple eccentric design ceramic butterfly valves have low friction and excellent tightness in abrasive mediums. Meanwhile operation torque of lug type ceramic butterfly valves is much lower than common metal seated butterfly valves.3. Ceramics-to-Ceramics seated

The disc sealing ring and seat are both high performance ceramics. High pure 99% Al2O3, Zirconia, Si3N4, and solid Tungsten carbide T.C. are used for Fuvalve lug type ceramic butterfly valves. Different ceramics materials are suitable for different applications. Fuvalve’s experienced engineers can help customers to select suitable materials for their specific applications. - Extended service life of ceramic butterfly valves can minimize maintenance cost for customers

Because of high hardness and excellent corrosion resistance of high performance ceramics, Fuvalve ceramic butterfly valves have much longer service life than any other common butterfly valves, and save maintenance cost for customers.Temperature range of Ceramic Butterfly Valve

-29℃~180℃ (normal)

-29℃~300℃(High Temperature)

Erosion resistance ceramic butterfly valve for fly ash