Abrasion resistant Ceramic ball valve for Powder Pneumatic Conveying

- Description

- Inquiry

Abrasion resistant Ceramic ball valve for Powder Pneumatic Conveying

As the most popular transportation method for powder materials all over the word,pneumatic conveying is more efficient,but the wear and abrasion problems normally occur in the pipebends and valves,where the conveyed material is subjuet to a high degree of turbulence,and system’s efficient will be reduced.

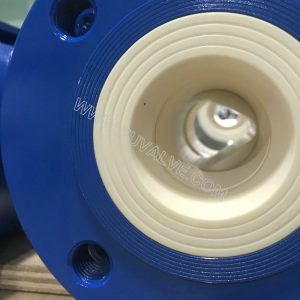

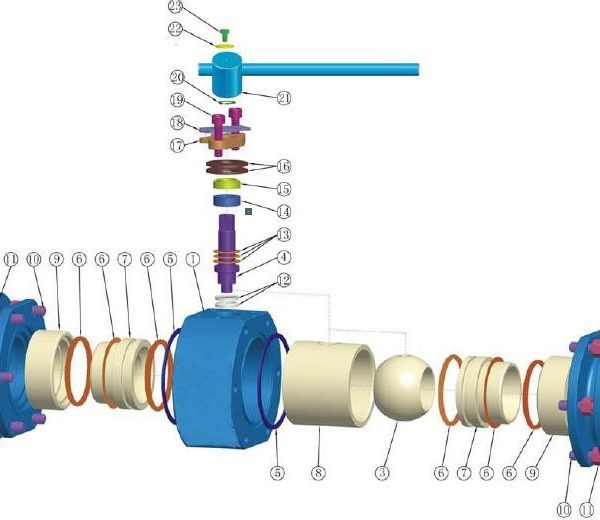

When alumina and zirconia ceramics are used in pipes,bends and valves,things get better,FUVALVE ceramic ball valves have a unique structure with ceramics lines the flow path,which ensure wear and abrasion are avoided significantly.Generally,the serice life of fully lined ceramic ball valve used in powder pneumatic conveying is about 3times longer than other valves.

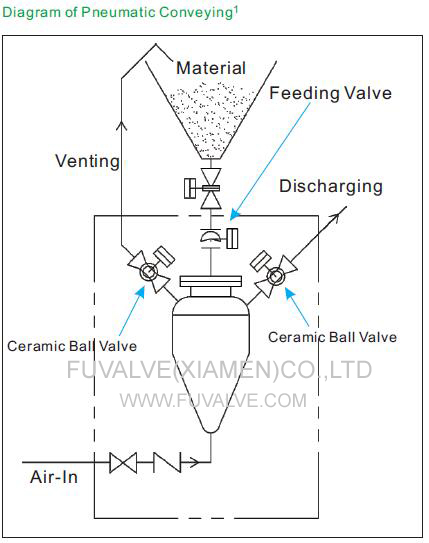

Diagram of pneumatic Conveying:

Main Industries served:

-Silicon powder

-Alumina powder

-Dry coal powder

-Limestone powder

-Cement

-Coalpowder injection

-Magnesium powder

-Quartz sand

-Metallurgical dust

-Petroleum solid catalyst

-Kaolin

Notes:

(1)This is a typical system,and others are also applicable.

(2)FUVALVE Ceramic semi-ball valve will be a good choice as a feeding valve.

Abrasion resistant Ceramic ball valve for Powder Pneumatic Conveying

FUVALVE full lined ceramic ball valves are widely used in all kinds of powder and solid materials including:

-Powder

-Resins

-Pellets

-Flakes

-Fiber

Typical Applications:

In many corrosive or/and abrasive applications, PTFE or PFA lined ball valves and metal seated ball valves are used, but limited to the material, these PTFE or PFA lined ball valves and metal seated valves cannot last for a long time due to severe abrasion and corrosion. Ceramic ball valve have excellent performance and much longer life time than soft seated and metal seated ball valves in most corrosive and abrasive applications. Some typical applications listed below (but not limited to these applications) where FUVALVE Ceramic ball valve have been widely used all over the world: Silicon Powder,Alumina Powder,Dry Coal Powder,Limestone Slurry,Gypsum Slurry,Plaster,Fly Ash,Mining Ore,Coal Powder Injection,Metallurgical dust,Thermal Power plant FGD,Petroleum Solid Catalyst,TiO2 suspension with sulfuric acid,Ammonia solution with powder,Hydrochloric Acid,Liquid Chlorine,Bulk Material.

Related Products

Flue Gas Desulfurization ceramic ball valve

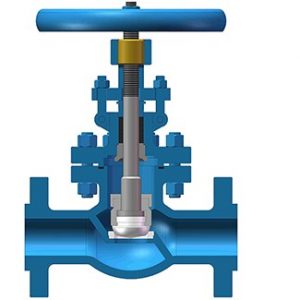

Bolted Bonnet Ceramic Globe Valves

3 pcs threaded end connection Ceramic Ball Valve

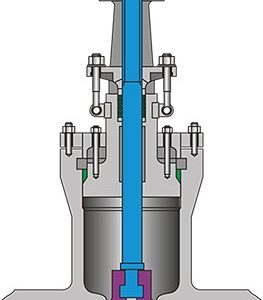

Pressure Seal Bonnet Ceramic Globe Valves

Angle Pattern Ceramic Globe Valves

Threaded end Ceramic Ball valve

Y Pattern Ceramic Globe Valves

Wafer Type Ceramic Butterfly Valves

Ceramic-lined Butterfly Valve

V-port Ceramic Ball valve