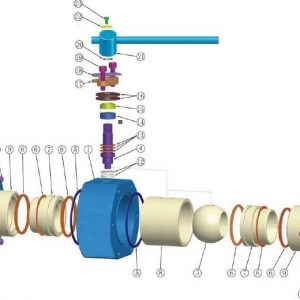

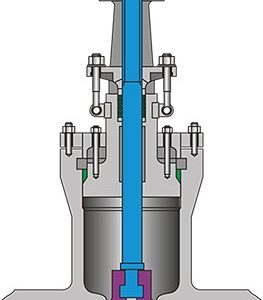

Ceramic Sliding Disc Valve

- Description

- Inquiry

Ceramic Sliding Disc Valve

Main specifications:

Nomunal pressure:1.0~6.3MPa

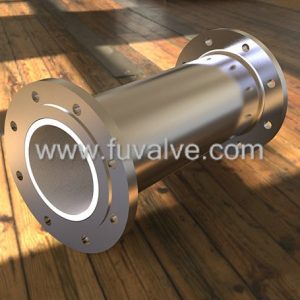

Nomunal diameter :DN40~DN300

Suitable media: Desulfuration,Dusting,Coal injection,Silicon powder converying

Suitable temperature :-20~500℃

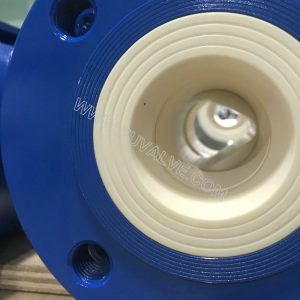

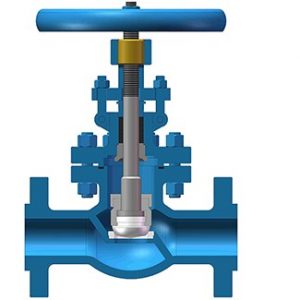

1、Ceramic to ceramic sealing The Sliding disc valve trim consists of three ceramic parts,one sliding disc and two stationary ceramic seats.The sliding disc is moving vertically and sealing against the seat directly.Compared with the traditional gate valve,it has long service life for there is no dead-space free,impact or impulse.

2、Abrasion resistant The hardness of the ceramic disc and seats is upto HRA88,maybe it is only less than Diamond.So the ceramic sliding disc valve has an outstanding performance in many high abrasion and wear applications.

3、Corrosion resistant Fine ceramic owns excellent chemical inertness , Almost no reaction with all chemical medium ,so the ceramic sliding disc valve can be excellent used to high-corrosion mediums.The design of sealing structure keep the medium from contacting the valve body cavity.

4、High strength The ceramic disc is protected by a metal holder,and the stem drives the disc through the holder,and the ceramic disc will not damaged for sudden shock.

5、Zero leakage With many years experience in ceramics machining,zero leakage is ensured for its high accuracy,the surface roughness and flatness of the sealing face are less than 2um.And the ceramic disc and seats grinding against themselves when open/close,for that the tightness of the valve is enhanced.

6、Without block The mediums especially which contains solid particle will not block the valve for the through conduit design and the unique dead-space free structure,that is why the ceramic sliding disc valve is very suitable for the abrasive and/or corrosive conditions.