Threaded end Ceramic Ball valve

- Description

- Inquiry

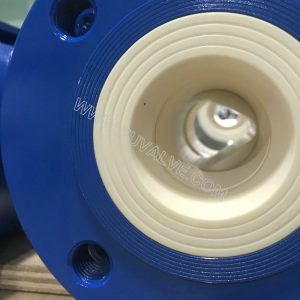

Threaded end Ceramic Ball valve

The common valves are easily worn and have heavy-torque because of soft seal,2-pcs ceramic ball valve have overcome this weakness with the ceramic valve ball inside.If there is a need,small actuators can be used to reduce the cost.In addition,the valves small and durable,and much maintenance cost unnecessary of the system can be saved.

Ceramic ball valves are different from the traditional valves,the valve ball and seats are made of structure ceramic.The products are applicable to water meter,calorimeter,solar water heater,and Natural gas pipe because of the good sealing properties,flexible and durable character(50-100 thousand times)

Suitable Pressure:1.0-4.0MPa

Suitable Temperature:-20 to 280 Deg C

Suitable medium:Water,oil and some abrasive liquid.

Advantages of ceramic ball valve include hi-economy, long life (2~4 times of Titanium Valves), increase resistance to corrosion, high temperature, wear and erosion etc.. They are commonly used in transportation systems of various acid, alkaline or saline gases, solutions, high working temperature steams and slurry, in the lines of oil industry, metallurgy, paper making, power station, refinery, etc. ceramic ball valves are the ideal substitute for titanium and montel valves in corrosive environments. There are four types of driving performances, manual, pneumatic, pneumatic-spring return and electric. Various special valves can be designed on demand. Furthermore, various high wear-resistant, corrosion-resistant and high temperature-resistant ceramic components, hydraulic pressure sealing components can be provided as well.

Threaded end Ceramic Ball valve

Datasheet of Technical ceramics

| Property | Units | Material | ||||

| 99.5% alumina | 99% alumina | 95% alumina | ZrO2 (Y-TZP) | ZrO2 (TTZ) | ||

| Density | g/cm3 | ≥3.85 | ≥3.80 | ≥3.60 | ≥5.95 | ≥5.72 |

| Water absorption | % | 0 | 0 | 0 | 0 | 0 |

| Hardness | HV | 1700 | 1700 | 1500 | 1300 | 900 |

| Flexural strength | Mpa | ≥379 | ≥338 | ≥320 | ≥1200 | ≥1200 |

| Compressive strength | Mpa | ≥2240 | ≥2240 | ≥2000 | ≥1990 | 1750 |

| Fracture toughness | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 11 |

| Max. service temperature | ºC | 1675 | 1600 | 1450 | 1000 | |

| CTE | 1×10 -6 /ºC | 6.5~8.0 | 6.2~8.0 | 5.0~8.0 | 8.0~9.5 | 10.2 |

| Thermal shock | T(ºC) | ≥250 | ≥200 | ≥220 | ≥300 | 350 |

| Thermal conductivity(25ºC) | W/m.k | 30 | 29 | 24 | 3 | 3 |

| Volume resistivity | ohm.cm | |||||

| 25ºC | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 | >1 x 10 11 | >1 x 10 11 | |

| 300ºC | 1 x 10 12 | 8 x 10 11 | 10 12 -10 13 | 1 x 10 10 | 1 x 10 10 | |

| 500ºC | 5 x 10 10 | 2 x 10 9 | 1 x 10 9 | 1 x 10 6 | 1 x 10 6 | |

| Insulation strength | KV/mm | 19 | 18 | 18 | 17 | 20 |

| Dielectric constant(1Mhz) | (E) | 9.7 | 9.5 | 9.5 | 29 | 28 |